Ten Steps To A New Chain And Sprockets

Changing a motorcycle chain is a relatively easy job for even the most inexperienced mechanic. Back in the old days, you needed little more than a hacksaw, a pair of vise grips and a correctly sized chain. Many beginning mechanics installed their first replacement chain in this manner. However, times have changed, and riveting master links, rather than clip connectors, are the standard. So, while the process is still fairly simple, you will need a specialized tool (or a friend that has one).

10. Inspect The Chain And Sprockets

First, you should inspect the sprockets. A worn sprocket will take its crooked teeth and chow down on your shiny new chain. So, look closely at the sprockets. Are the sides of the teeth worn? If so, expect to find a matching wear pattern on the inside of the chain. Do the teeth of the sprockets look like cresting waves? Are teeth — gasp — missing? If you answered yes to any of these questions, you definitely need new sprockets. At the very least, should change an aluminum rear sprocket with every new chain. The soft aluminum tends to wear more quickly than the OE steel sprockets. However, if your aluminum sprocket is hard anodized, it should withstand a couple of chain replacements.

9. Decide If You’re Changing Your Gearing

Once you’ve determined you need both chain and sprockets, you have a few decisions in front of you. First, are you going to keep the stock gearing? Like hand and foot control positions, the gearing that comes with your bike is a compromise designed to give you the best performance over a wide range of possible uses for your bike. People doing top speed runs on dry lake beds and stunters who live for wheelies have little in common when it comes to gearing needs. The rest of us fall somewhere in between. Still, you can shift your peak power relative to your speed by tweaking the number of teeth on your sprockets. For example, if you install a front (countershaft) sprocket with fewer teeth, you will gain in acceleration at the expense of top speed. The same is true of adding teeth to the rear. As a rule of thumb, every tooth removed from the countershaft sprocket is the approximate equivalent of adding two to the rear.

Why would you want to do this? Racers use the gearing to tune their engine speed for the exit of key corners. With the exception of some super-high-speed tracks, the launch out of the corner is vastly more important than the top speed of the bike. So, if you reduce the number of teeth on the front or add them to the rear, what can you expect? Acceleration around town will be quicker. Your bike may feel snappier when you roll on the throttle, but there’s no free lunch. Since you’ll be running the engine at higher rpm for all speeds, your gas mileage will drop. On the interstate, you will notice that the engine feels busier. If you’re still unsure about what to do, ask other riders who do the same sort of riding you do if they’ve changed their gearing.

8. Remove The Countershaft Sprocket

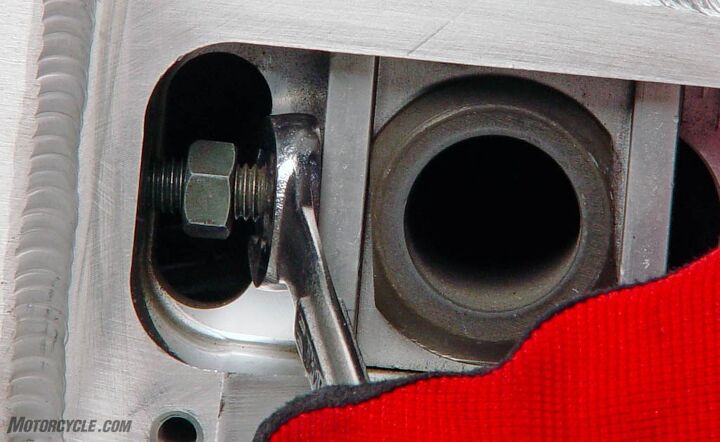

When changing the chain and sprockets, start by freeing up the countershaft sprocket while you still have a way to lock it down. Countershaft sprockets are usually secured one of three ways: a pair of bolts securing a plate to the sprocket, a big clip that slips into a groove in the countershaft itself, or a really big nut. For the pair of bolts, simply put the engine in gear, press on the brake pedal, and unbolt them. Follow the first two steps for the clip, but slip it off with a flathead screwdriver instead. The really big nut provides the biggest challenge. Using a punch or big flathead screwdriver bend the tabs on the lock washer that have been folded against the flats of the nut.

Since the nut was torqued to at least 65 foot-pounds and may have thread lock on it, you’ll need to secure the rear wheel before you attempt to break the nut free. Slip a piece of pipe or 2×4 through the rear wheel just above the swingarm. Now, when you muscle the nut free, the wood will keep the wheel, chain and sprocket from moving.

7. Remove The Chain

Once the countershaft sprocket is broken loose you can begin removing the chain. Clip-style master links are easy — too easy — to remove. Slip the clip free with a flathead screwdriver. Next, walk the removable plate off the pins by alternately prying the ends with a screwdriver. Eventually, the plate will pop free.

With endless chains or riveted master links, if you don’t have a chain breaker, a hacksaw will do the trick. If you have a chain breaker, you may or may not (depending on the strength of the breaker and the size of the chain) need to grind off the head of the roller pin. Usually, the midpoint between the two sprockets will be the most unobstructed place to break the chain.

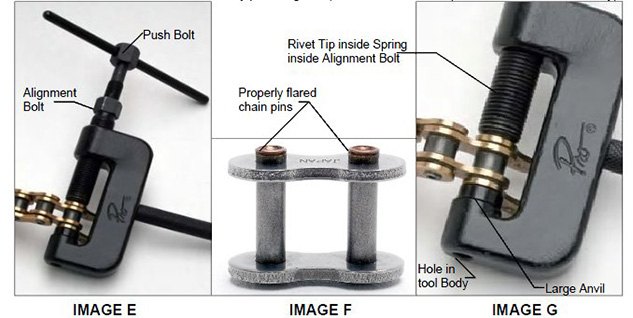

Motion Pro’s Chain Cutter & Riveting Tool is about the best one around, though the company also sells less expensive units. Install the correct size breaking tip in the tool, making sure that the tip is withdrawn at least 2mm inside the alignment bolt. Center the pin in the tool and tighten down the alignment bolt with a 14mm wrench to hold the tool in position. Using the 14mm wrench, crank the extraction bolt so that it pushes the breaker tip and the roller pin out of the bottom of the tool. When the pin falls free, back the extraction bolt out until the tip is back inside the alignment bolt. Loosen the alignment bolt until the chain falls free. Repeat if necessary for a master link.

6. Replace The Sprockets

Before you install the new chain, you’ll need to replace the sprockets. To remove the rear wheel, first loosen the chain adjusters three full turns and snug up the lock nuts to hold them in place. Remove the axle nut and axle. Lay the wheel down sprocket-up. Using a socket, remove the nuts from the studs securing the sprocket in a crisscross pattern. Slide the old sprocket free. If the stud threads are greasy, clean them with contact cleaner. (If you’ve been neglectful in your wheel cleaning because the sprocket was in the way, now would be a good time to take care of any mung sullying your wheel.)

Place the new sprocket on the studs. If you’re unsure of the orientation, the number of teeth on the sprocket is usually stamped on the side facing out. Screw the nuts down finger tight. Set your torque wrench to half of the value specified in your factory service manual and tighten the nuts in a crisscrossing pattern. Once all nuts are torqued halfway, set the full torque value on your wrench and tighten the nuts again. If you tighten the nuts down to their full -torque setting in one step, you run the risk of stripping the threads. Remount the wheel and loosely fasten the axle nut.

Since you’ve already loosened the countershaft sprocket, you should be able to spin the nut free. Before you pull the sprocket off, take a look at it and any spacers positioning it on the countershaft. Don’t worry if the OE sprocket has noise-reducing rubber on the sprocket; most aftermarket sprockets don’t. While you have the sprocket off the countershaft, take a quick look at the seal with the engine case. You shouldn’t see any leakage. Take advantage of the easy access you have with the sprocket removed to clean all the encrusted chain goop from the surrounding area. Clean the countershaft, paying particular attention to the threads for the nut, with contact cleaner. Once the contact cleaner is dry, slide the sprocket onto the shaft. Don’t worry about the nut(s) yet. You’ll torque it down once the chain is installed. Clip-type sprockets can have the clip pushed into place with a big screwdriver.

5. Measure/Cut The New Chain

If you’re using the same size sprockets, lay the old chain down on a clean surface beside the new one to mark the length. Now, pop the pin out of the new chain to cut it to the correct number of links. For different sprocket sizes, you’ll measure the chain to length once the sprockets are mounted. Wrap the new chain around both sprockets. If the chain has not been cut to length, turn the chain adjusters in equal amounts until the middle of the adjustment range is indicated on the swingarm. Snug up the axle nut to keep the axle from moving. Pull the chain taut and fold the chain over where it meets the other end. You goal is to mark the rivet that needs to be removed so that you can slip the master link into position. Remove the rivet as described earlier.

4. Install Master Link

Master links used to come in two varieties: clip-type and rivet-type. If your chain only came with a clip-type link, either return it for one with a rivet master link or go buy one for the chain. Clipping-type master links have a nasty habit of tossing their clips and sometimes the entire link – despite the fact that the clips are a pain to install. A thrown chain can cause Very Bad Things to happen.

When removing a master link from its packaging, make sure you don’t wipe any grease off the pins or O-rings. If your chain includes a tube of grease, apply a hefty amount to the pins, O-rings, and plates. Many times when you cut a chain to length, the O-rings will stay mounted on the inner links. If so, remove them. Install the O-rings included with the master link on the pins. Push the pins of the master link through the chain from the back. When you’re happy with its position, check/ and install the O-rings on the front of the chain and press the outer plate on with your fingers.

3. Press/Rivet Master Link

Assemble the chain-rivet tool with its press plates. Using a wrench, tighten the bolt until the plate is seated. If your rivet tool doesn’t have press plates, you can “walk” the plate into position by clamping down a pair of Vise-Grip pliers on alternating ends of the plate. Tighten the pliers’ adjuster a little between each step. Whichever technique you use, your goal is to have the outer side plates on the master link the same distance from the inner plates as on the adjoining, permanently riveted links. Proper alignment will make sure that the grease stays in the roller when the chain gets hot, but without the master link being so tight that it binds the chain.

Properly riveting the roller pins is vital to keeping your chain together. Use the right tool for the job, and you’ll have no worries. Place the chain tool’s anvil behind the pin you’ll be riveting. Line the pin up in the tool and tighten the alignment bolt. Push the riveter onto pin with the tool’s push bolt. Tighten the bolt down until it flares the end of the pin, preventing the plate from sliding out on the pin. Repeat on the other pin.

[Image Credit: Motion Pro]

2. Torque Countershaft Sprocket Nut

The sprocket nut needs to be torqued down to prevent it from backing out at speed. Install any washers required. Use a new lock washer. Add a few drops of blue Loctite on the countershaft threads and the nut. Secure the countershaft by stopping the rear wheel as you did for the nut removal step. Torque the bolt to factory specification. If your countershaft sprocket was secured with a locking washer, be sure to install a new one.

1. Adjust Chain Slack

Since you loosened both chain adjusters three turns, they should still allow for proper axle alignment. Follow your usual chain-adjustment routine and tighten each tensioner in equal increments until the proper amount of chain slack is reached. With the exception of eccentric adjusters, you can only move the axle away from the countershaft sprocket via the adjusters. So, don’t get carried away or you’ll have to start all over from scratch. Small adjustments of a quarter turn (or less if your chain is only slightly loose) are the safest bet. Measure the slack after every change. When the chain is within factory specifications (usually around 1.2-1.5 inches), tighten the axle nut to keep it from slipping. If you go too far and the chain becomes too tight, loosen the chain adjusters two full turns and use a rubber mallet or dead-blow hammer to knock the rear wheel forward against the adjusters and begin again.

When the chain has the proper amount of slack, torque the axle nut. Next, tighten each adjuster about one eighth of a turn against the axle. Hold the adjuster in position and set the lock nuts.

Like most of the best happenings in his life, Evans stumbled into his motojournalism career. While on his way to a planned life in academia, he applied for a job at a motorcycle magazine, thinking he’d get the opportunity to write some freelance articles. Instead, he was offered a full-time job in which he discovered he could actually get paid to ride other people’s motorcycles – and he’s never looked back. Over the 25 years he’s been in the motorcycle industry, Evans has written two books, 101 Sportbike Performance Projects and How to Modify Your Metric Cruiser, and has ridden just about every production motorcycle manufactured. Evans has a deep love of motorcycles and believes they are a force for good in the world.

More by Evans Brasfield

Comments

Join the conversation

Why oh Why does every chain NEED to go through the Swingarm. With true engineering excellence surely a way could be found to create one which allows the chain to be freed by removing the swingarm , thus allowing an endless chain to be installed without the compromise of a joining link.