MO Wrenching: Why You Need A Torque Wrench

Trusting your feel can lead to expensive mistakes

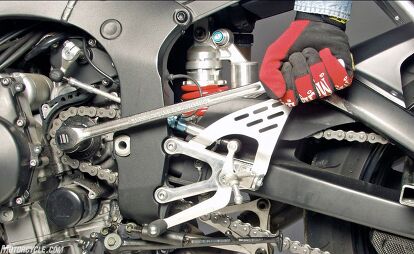

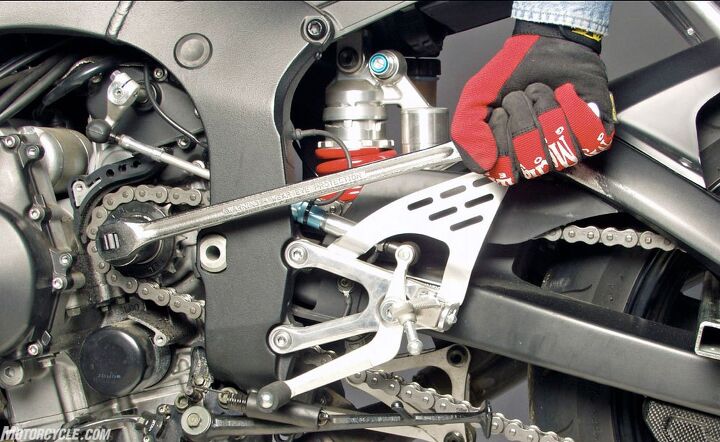

All mechanics, even casual ones, should have a torque wrench – or two. Why? Because if you don’t torque a fastener down tight enough, you risk having it vibrate loose. Go too far when tightening something, and you’ll strip the threads or break the fastener. Torque wrenches come in a couple varieties. The least expensive (and least useful) is a wrench that has two bars. The first is the hand grip and the second is the pointer. As you tighten a bolt you bend the bar with the handle, moving a gauge under the pointer. Don’t waste your money on this type. Not only is it not terribly accurate, but also it requires that you be able to look at the wrench while using it. The tight spaces of motorcycles don’t always allow this to happen.

The type of torque wrench you want to use one that you can set the value you wish to achieve while tightening a fastener. When you crank on the wrench, it will release with a click when the specified torque is reached. While you can buy torque wrenches with either pound-feet or Newton-meters (SAE or metric), I recommend getting a torque wrench that has both measurement scales. Often, you will get instructions with one torque figure but not the other. A dual-scale wrench saves you from having to convert the figures. (However, there is an app for that.) If you can only afford a single torque wrench, select one that has a range from 20 to 100 or more pound-feet. If you can afford a second torque wrench, buy one in inch pounds (with a range up to 20 pound-feet), too. Motorcycle fasteners are expensive so don’t count on “feel” when you’re wrenching.

While you’re using a torque wrench, you still have to use common sense when tightening nuts. For example, torquing down the nuts securing a rear sprocket should be done in stages. Set your first torque value at about the halfway point, torque all the nuts in an alternating pattern, and then repeat at the full value. If you try to go for the full value at once, you can strip the studs. Bigger nuts, like axles, don’t need the intermediary step. Also, unless otherwise stated, torque values are for dry threads. If you lubricate the threads, the lowered friction between the threads can allow you to exceed the recommended stretching force of the fastener, which can lead to damaged threads or broken fasteners.

One final word about torque wrenches: they are precise, expensive instruments. Don’t use them as a breaker bar. It’s tempting to turn the torque wrench all the way up and use the extra length to crack loose a stuck fastener. Unfortunately, you can ruin your torque wrench if you’re not careful. Breaker bars have been designed solely for this purpose and are considerably cheaper. Although breaker bars are usually as long as a torque wrench, you can lengthen them with a piece of pipe for those times you need even more leverage. Just be careful not to twist the head right off the bolt.

General Fastener Torque Table | ||

|---|---|---|

| Thread diameter (in mm) | Newton meters | pound-feet |

| 5 | 3.4-4.9 | 30-43 (inch pounds) |

| 6 | 5.9-7.8 | 52-69 (inch pounds) |

| 8 | 5.9-7.8 | 10-13 |

| 10 | 25-34 | 19-25 |

| 12 | 44-61 | 33-45 |

| 14 | 73-98 | 54-72 |

| 16 | 115-155 | 83-115 |

| 18 | 165-225 | 125-165 |

| 20 | 225-325 | 165-240 |

These general torque figures were culled from a variety of service manuals. For the gospel according to your specific bike, consult the factory service manual.

[This article was adapted from Evans Brasfield’s book 101 Sportbike Performance Projects. Learn more about it here. Read the MO review here.]

Like most of the best happenings in his life, Evans stumbled into his motojournalism career. While on his way to a planned life in academia, he applied for a job at a motorcycle magazine, thinking he’d get the opportunity to write some freelance articles. Instead, he was offered a full-time job in which he discovered he could actually get paid to ride other people’s motorcycles – and he’s never looked back. Over the 25 years he’s been in the motorcycle industry, Evans has written two books, 101 Sportbike Performance Projects and How to Modify Your Metric Cruiser, and has ridden just about every production motorcycle manufactured. Evans has a deep love of motorcycles and believes they are a force for good in the world.

More by Evans Brasfield

Comments

Join the conversation

Great info Evans, thanks!

I've been told by people I believe know what they're talking about that you should always set your torque wrench to 0 when it's not in use. They say keeping the tool wound up to high torque settings takes them out of adjustment faster than necessary.