Touring Harley-Davidson's Pilgrim Road Powertrain Operations Plant

State-of-the-art assembly increases both efficiency and worker safety

Since the Milwaukee-Eight engine was announced last year, much has been made of Harley-Davidson’s newest powerplant. The Motor Company increased power output while maintaining fuel efficiency in the all-new engine. Well, the updates didn’t stop with the engine itself. Over the two years prior to the engine’s release, the Pilgrim Road Powertrain Operations Plant had quietly been upgraded to handle the stringent manufacturing requirements of the new engine. (In fact, this update was the reason we weren’t let into the facility when we showed up on a road trip last year, as described in this article.)

2017 Harley-Davidson Milwaukee-Eight Engines Tech Brief

Testing Harley-Davidson Screamin’ Eagle Upgrade Kits For Milwaukee-Eight Engines

A few months ago, the folks at Harley made good on their offer for us to look at the factory by throwing open the doors and giving a few members of the media a special tour of the operation. During this extended walk, we received the inside skinny from two people who should know a thing or two about how things work in the plant. David Fish and Jared Olsen, whose job titles, Manager of Engineering, Manufacturing, point to the fact that they are more than tour guides. They play an important role in setting up and running the plant’s daily operations.

The 912,000-square-foot Pilgrim Road Powertrain Operations facility is located in Menomonee Falls, Wisconsin, in which it manufactures and assembles the Big Twin, Milwaukee-Eight and Sportster engines and transmissions that will ultimately be mounted in bikes at the final assembly plants in York, Pennsylvania, and Kansas City, Missouri. Additionally, the plant’s employees produce powertrain kits, which are then shipped to two assembly plants in Manaus, Brazil, and Bawal, India. If that weren’t enough, any engines and transmissions sold through the Harley-Davidson Genuine Motor Parts and Accessories side of the business also trace their genesis to Pilgrim Road.

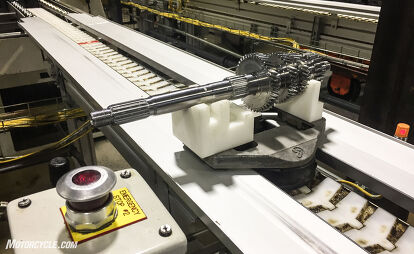

Our tour began in the section of the plant devoted to the automated process of creating the engine top ends. Using a system developed alongside the Milwaukee-Eight engine, robots load and unload the heads into various machining cells. Parts are transported overhead to reduce floorspace footprint. Testing of parts takes place concurrently with the manufacturing, with the heads coming off machining units and immediately being tested for leaks in their cooling system.

This simultaneous testing and machining plays an important role in keeping the parts’ specifications from “drifting” over time, which happens in all manufacturing processes. As the parts are measured, the system is smart enough to adapt to any change trends and instruct the automated machining cell to alter its process to halt the drift before it becomes a problem. The same is true for the cylinder dimensions – even down to the level of the cross-hatching on the cylinder walls.

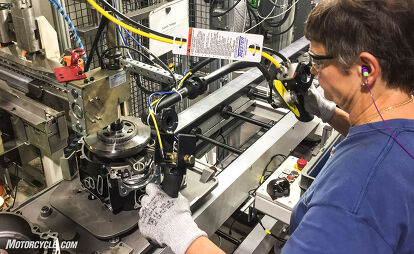

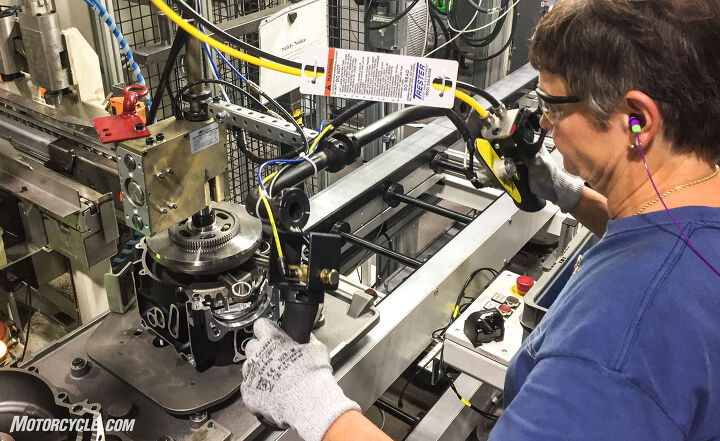

Fish stressed that, while automation brings in increased efficiency and control of manufacturing tolerances, the primary driver for automating processes is often the safety of plant employees. Think about it: Constantly moving and precisely placing components that range in weight from 10 to 30 lbs. will take a physical toll over the course of a work day – not to mention a lifetime. Machine assistance that is controlled by the employees makes for quicker, more accurate assembly with less chance for injury. This quality control repeatability combined with the reduction in long-term wear and tear on the technicians benefits both the company and employees.

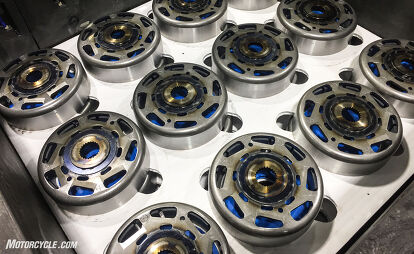

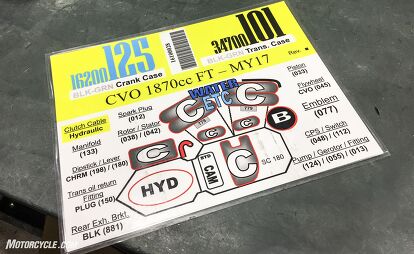

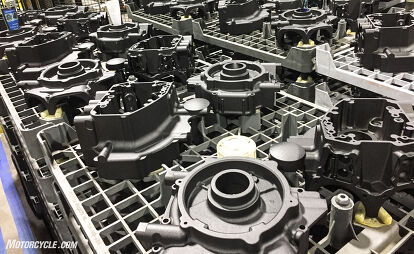

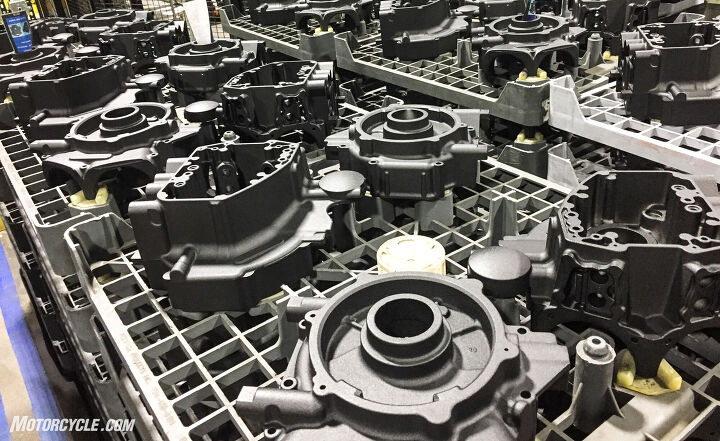

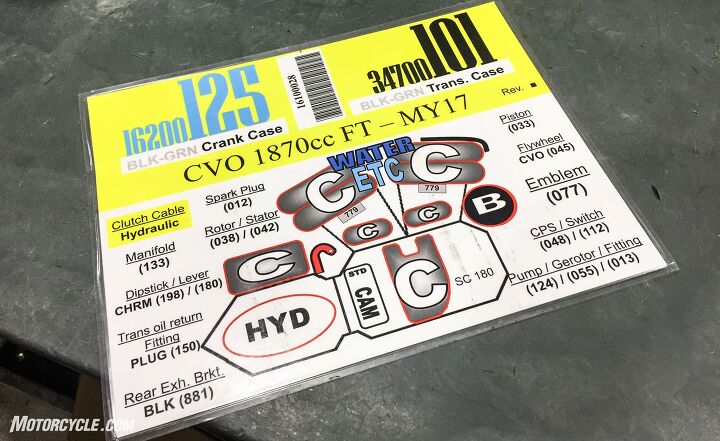

Because of the preciseness of the machining enabled by the automation, the parts can be machined to match their individual tolerances. Crankcases are married as sets and are machined to be used together. Each half is machined as individual part and then bolted together to form a married pair that will only meet specifications together. Each part has a unique code on it that allows it to be tracked throughout the process. Building the cases is completely automated. Not until final assembly and inspection do humans actually touch the pieces. Before the parts are mated, they are washed, dried, and then receive a final blast of compressed air on the mating surfaces to make sure no foreign matter interferes with the seal.

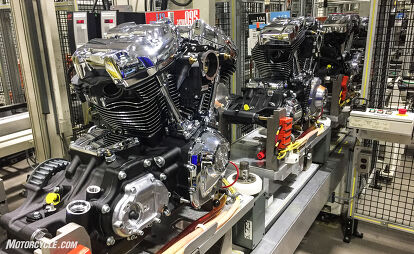

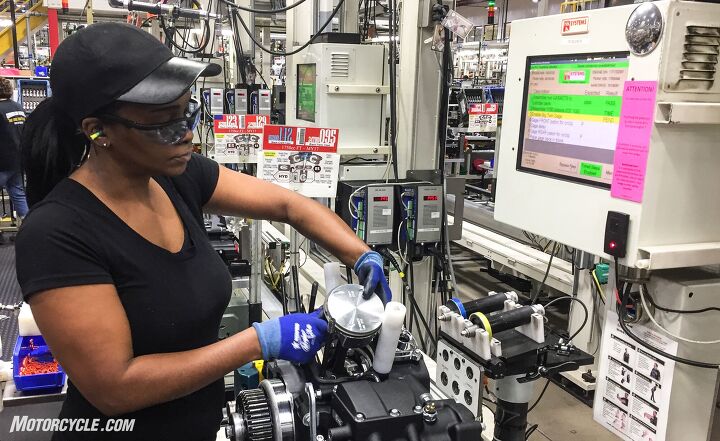

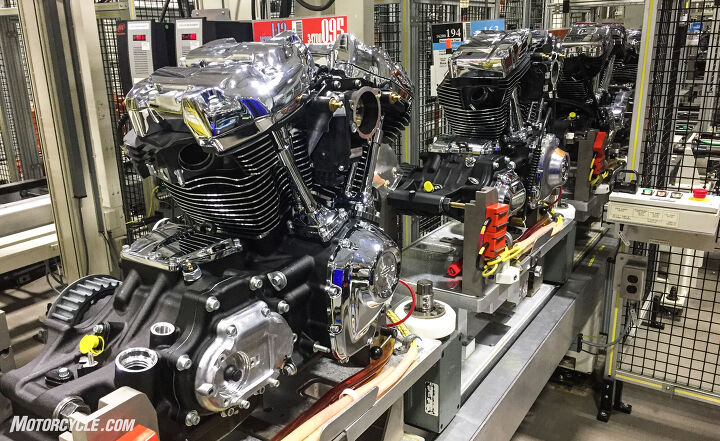

Once the parts are all machined, they move to the assembly floor. As mentioned before, the Pilgrim Road plant produces Milwaukee-Eight, Twin-Cam, and Sportster engines. However, you may be surprised to learn that all three engines are assembled on the same line at the same time. A line worker may get to work on all three engines in a row.

According to Olsen, when the various finish options and displacements are considered, the lines can produce any of 42 different engine assemblies at the same time. The process is designed to have the engines sitting outside of their frames for a minimal amount of time. So, they are built to order with travel time considered to go into the frames shortly after their arrival at the final assembly facilities. This is why all the flexibility is built into the assembly line. It allows the company to fine-tune manufacturing to match which particular models are selling at any given time. When it comes to customer orders of engines alone, the goal is to have it leaving the factory within three days.

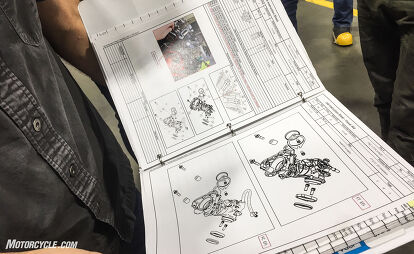

As the components arrive, the technician’s work station recipe tells them which parts to install and which order. If fasteners are required, the work station displays the order in which they should be tightened and the torque settings are automatically adjusted by the system. These torque figures and the angle at which they were applied for each fastener are then collected and put into the history file of each engine for future informational use. Also, when a shift ends, the technician simply finishes the step they’re on, and the workstation’s recipe tells the next person who comes on the line where to start.

In the end, all of this attention to detail results in a manufacturing process that can manage the flexible requirements of adjusting its output to account for seasonal and customer purchasing trends. Additionally, Harley has strived to deliver efficiency that pays off both in terms of bottom line and in the reduction of manufacturing waste. In September 2016, for the first time ever, Pilgrim Road transferred zero manufacturing waste to landfills.

Look at the photos that follow to take a virtual tour through Harley-Davidson’s Pilgrim Road Powertrain Operations Plant.

Like most of the best happenings in his life, Evans stumbled into his motojournalism career. While on his way to a planned life in academia, he applied for a job at a motorcycle magazine, thinking he’d get the opportunity to write some freelance articles. Instead, he was offered a full-time job in which he discovered he could actually get paid to ride other people’s motorcycles – and he’s never looked back. Over the 25 years he’s been in the motorcycle industry, Evans has written two books, 101 Sportbike Performance Projects and How to Modify Your Metric Cruiser, and has ridden just about every production motorcycle manufactured. Evans has a deep love of motorcycles and believes they are a force for good in the world.

More by Evans Brasfield

Comments

Join the conversation

And where are the modern Street model engines built? It's nice to see elderly push rod motors built in such a nice place but where does Harley build their next generation motors?

Did you find out if and when the Dyna gets the Eight? All of my wants and desires in the motorcycle universe have boiled down to a Street Bob with the biggest engine and best suspension I can get. At least, until Motus and Arch get the price right.