2017 Harley-Davidson Milwaukee-Eight Engines Tech Brief

New tech for a historic V-Twin

The first Harley-Davidson V-Twin engine was released in 1909 in the form of the Atmospheric V-Twin. Since that time the Motor Company has sold a total eight V-Twin engine designs – Atmospheric V-Twin, F-Head, Flathead, Knucklehead, Panhead, Shovelhead, Evolution, and Twin Cam – most of these names are instantly recognizable to almost any motorcyclist. So, when considering the relative rarity of Harley engine redesigns and the importance of the engine to one of the world’s biggest motorcycle manufacturers, you can bet that any major changes are well thought out and refined to a degree that lesser OEMs might have a tough time matching. With all that’s literally riding on a new engine, Harley’s project planners turned to the tools that have worked the best in recent years.

2014 Harley-Davidson Touring Lineup Updated With Project Rushmore Enhancements

Harley’s Project Rushmore, unveiled only three model years ago in 2014, turned to members of the riding public to quantify what they wanted in a touring motorcycle. For the 2017 touring models, Harley’s researchers and engineers again picked the brains of both current Harley touring bike owners and riders who are interested in the marque but haven’t yet pulled the trigger. The result is the new Milwaukee-Eight engine. With interviews conducted in seven cities around the world, 1,000 riders were asked to outline what they would like to see in the next generation of H-D touring bikes.

Over time, several common themes became clear to the designers. First – and this should come as no surprise to any motorcyclist – these riders wanted more power from the 45° V-Twin. These requests were further broken down into two major groups: those who wanted more roll-on power and those who wanted the hot-rod feeling of power building all the way to the rev limit.

Second, riders wanted more comfort. Engine heat plays a dramatic role in rider comfort both out on the highway and when cruising around town, and riders made it clear that they wanted less heat flowing up from the rear cylinder and exhaust system – not just for themselves, but their passengers, too. Also, some riders – in this case, frequently potential Harley owners – wanted reduced vibration.

Harley-Davidson Unveils The Milwaukee-Eight Engine For Touring Models

One area that lanky Americans and Central Europeans may forget is that the rest of the world is significantly shorter in the inseam. So, these focus groups pointed out that they would like for the touring models to fit their shorter statures better. Finally, and most importantly, the updated models needed to have the look, sound, and feel of a Harley-Davidson. The consensus among the interviewees was summed up by Alex Bozmoski, Chief Engineer of the Milwaukee-Eight Project, as “I want it to look like a Harley-Davidson from a football field away, but I want it to look like a new Harley-Davidson from 25 feet.”

More Power

The most obvious change in the powerplant is right there in each engine’s model name: Milwaukee-Eight 107 and Milwaukee-Eight 114. The Twin Cam 103 engine grew to 107 cu. in. thanks to its new bore and stroke of 3.937 in. x 4.375 in. (99.999mm x 111.125mm) while the 110 jumped up to 114 cu. in. via its 4.0-in. x 4.5-in. (101.6mm x 114.3mm) bore and stroke. However, the changes go much deeper than having bigger lungs to fill. The four-valve head is said to flow 50% more than the Twin Cam’s – a good thing since the Screamin’ Eagle big-bore kits can bump the displacement to 114 cu. in. and 117 cu. in. respectively, and that’s before we even consider the home-grown hop-ups that many H-D engines receive.

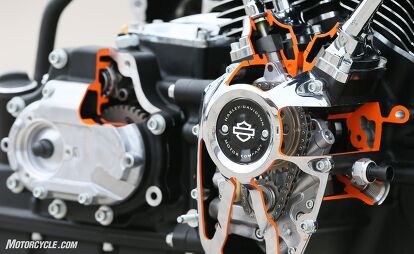

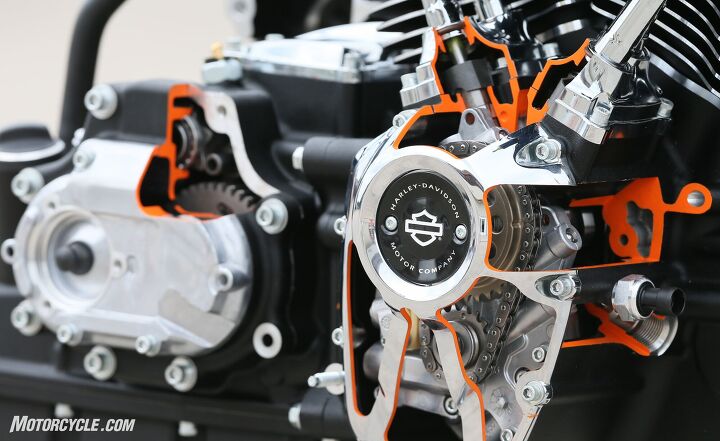

Still, this ground-up revision of Harley’s venerable V-Twin is more than just mounting a pair of bigger jugs.The four-valve head brought its own design considerations into play. The entire valve actuation system changed. Some readers may not remember that prior to the Twin Cam engine, the Evolution series utilized a single cam. With the Twin Cam the change was required to help reduce the angles on the pushrods to allow for higher valve lifts and more aggressive tuning, and these challenges couldn’t be solved without switching to dual cams. However, current modeling technology has allowed for the single cam to return, bringing with it multiple advantages: less parasitic power losses, less complexity, and less mechanical noise (one of the engine’s primary design goals). The switch to a four-valve head also had other benefits. Smaller valves have lower mass, requiring less spring to close, which results in a lessened impact on the valve seat. This reduced the beating the valve seats take and translates into lessened valve wear and lower noise.

Another interesting feature of the new heads is the lack of left-to-right valve lash adjustment on the pairs of intake and exhaust poppets. Today’s tighter manufacturing tolerances allow for the variance in the gap between the fingers and the valve stems they actuate to be reduced to a mere 0.003 in. It takes a variance of 0.010 in. to be able to hear the valve noise and see accelerated wear. With that difference reduced, the engineers determined that no lash adjusters needed to be installed.

“The cure was worse than the disease, putting the adjustment in caused you to have more adjustments.” said Bozmoski, “It was the thing that wore the most.” So, once the valve lash is set at the factory, no adjustment will be required for the life of the engine. Bozmoski stresses, ”After one and a half million miles and over 7,000 hours of accelerated dyno durability, you don’t see any of them needing an adjustment. They wear together.”

Feeding the new heads, a new Mikuni throttle body is 5mm bigger, at 55mm, compared to the previous one. The ignition system gained individual knock sensors on each cylinder to dynamically fine-tune the spark timing to deliver optimum power while also reducing the heat produced by the engine. According to Bozmoski, the switch from ion-sensing knock sensors to cylinder-mounted ones dramatically increases the range of individual cylinder spark control the ECU has over the firing of the twin plugs, allowing as much ignition advance as possible. “So, you’re not creating heat by retarding the spark to keep yourself away from knock,” explains Bozmoski.

Since knock increases exhaust gas temperature (EGT) and in extreme cases can damage the engine, the Milwaukee-Eight’s ignition timing can be retarded right up to the point of the first signs of predetonation, which has no sound, and then be walked back until it stops. Managing ignition timing to the ragged edge of detonation delivers not only more power with less heat, but it also burns cleaner for fewer emissions, allowing the largely air-cooled engines to meet the strict Euro 4 standards while delivering within 2-4% of the performance of engines tuned to meet U.S. standards.

Harley reps stressed that touring model owners aren’t as interested in fuel economy as they are in the ultimate range of their bikes. So, in those terms, the Milwaukee-Eight engine produces more power while still maintaining similar or better range per tank, so that points to the Milwaukee Eight’s mpg being the same or better as the Twin Cam’s.

The reduction of the EGT by roughly 100° F also helps to meet one of the comfort goals of the Milwaukee-Eight. The heads and the pipes run cooler, and when combined with the relocation of the hot catalytic converters further from the cockpit, dramatically reduce the heat reaching the rider and passenger. Still, the cooler heads are the product of more than just better engine management. The cooling built in to the redesigned heads also plays a key role.

Oil-Cooling vs. Water-Cooling

Since water (the primary component of antifreeze) has a much higher thermal conductivity than oil, the cooling passageways around the exhaust valves needed to be designed differently for the oil-cooled models versus the Twin-Cooled ones. One of the hottest places in the head is the bridge between the two exhaust valves. Since water is so much more efficient at drawing away heat, a heart-shaped core only needs to get close to the bridge to effectively reduce the heat. On the oil-cooled engines, the cooling passages are actually drilled through the bridge, giving the oil access to the hottest point on the head so that the oil can carry the heat away. (A quick note: The half-quart increase in oil capacity in the Eight is not because of the increased heat the oil is subjected to but, rather, is used to allow extra time to reduce the aeration of the oil before being recirculated.)

Managing Vibration

Harley’s design engineers focused a lot of time and effort on finding the right amount of vibration in the M-E to appeal to both the hard-core, traditionalist rider and the rider who looks at the engine jumping around in the frame at idle and thinks it can’t be comfortable or smooth at speed. When test engines were made with more complete vibration damping, the core Harley riders were unhappy while the potential H-D customers were satisfied. Since the core couldn’t be alienated in search of new Harley owners, a happy medium was eventually found in which vibration was reduced by 75%, providing a compromise where both factions felt the vibration was appropriate.

Reduced Mechanical Noise

We’re all aware of the EPA’s restrictions on a motorcycle’s noise signature, but not everyone may realize that by reducing an engine’s mechanical noise, there is more room left on the dB meter for things that riders like to hear, like the exhaust note. So, when it came to managing the M-E’s sound output, Bozmoski noted, “Our recipe is exhaust dominant. Everything else, we try to pull back.”

As mentioned above, the switch back to a single cam and the new heads took strides to minimize mechanical noise. Still, Harley’s engineers even eliminated mechanical noise that wouldn’t be a factor in the EPA sound level testing. For example, the first gear cog in the transmission is preloaded with a spring to reduce the rattle that can be heard when the engine is idling in neutral. A similar approach was taken with the counterbalancer. All of this adds up to a tighter sounding engine.

Other Notable Changes

In the transition from Twin Cam to Milwaukee-Eight, approximately 20 lb. of components were added to the engine. However, through tight packaging, the overall delta in engine weight is neutral, according to factory reps. Harley’s engineers accomplished this by carefully selecting where the weight would be utilized. For example, the crankcase is bigger with the balancer up front, which translates into more surface area. While making this larger case 25% stronger, the weight remains the same as the Twin Cam’s. Additionally, the flywheel has 20% more inertia to help smooth throttle response, but through finite element analysis, the weight and strength were put where they were needed, resulting in what H-D claims is a zero weight penalty.

The charging system received an upgrade. With the idle rpm dropped from 1,050 rpm to 850 rpm as part of the heat-reduction program, the previous system couldn’t put out enough amperage to maintain a positive charge, so it was doubled in size. Now, at 1,000 rpm, it puts out 34 amps instead of 17 amps.

The clutch was upgraded to a torque-assist unit which requires 7% less effort at the lever thanks to the lighter springs used. The new clutch also gives better feedback at the lever. With a torque assist clutch, the more torque applied to the clutch pack, the harder it grips. Since many Harley owners build their engines, this means that the clutch will be able to handle the increased output. However, the clutches are different on the 107 engines and 114 engines, which get a nine-plate and ten-plate clutch, respectively. Still, even with the changes, the derby cover is narrower than on the Twin Cam, allowing a rider an easier reach to the ground.

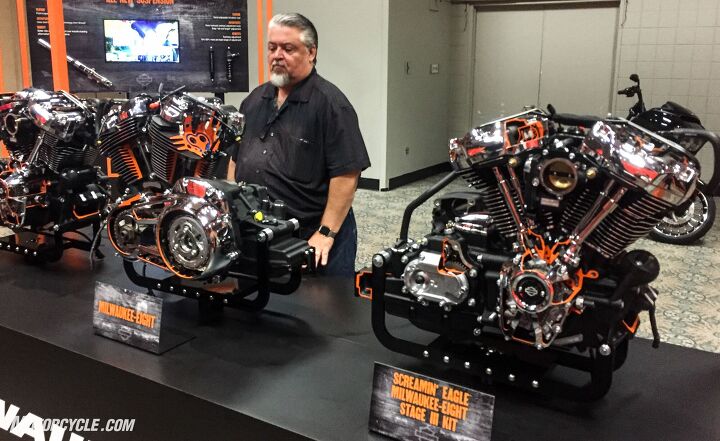

Screamin’ Eagle

In a break from the past, Harley is releasing the Screamin’ Eagle hop-up parts at the same time as the engine itself. This is good for two reasons. First, it points to the fact that the performance parts were developed concurrently with the engine itself. Second, buyers can roll the parts into their loans at the time of purchase. Remember, these kits are covered under the factory warranty, so there is a distinct advantage with going with the OEM hop-up versus the aftermarket.

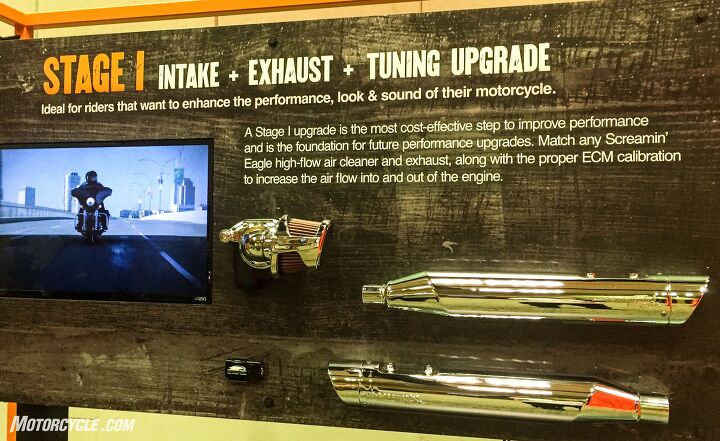

The kits come in four stages. Stage I is the easiest for the user to install and consists of an intake, exhaust, and tuning upgrade. Stage II adds a cam in a choice of two different profiles: torque/mid-range roll-on-focused or peak-horsepower focused. (Remember the two groups of power hungry riders noted at the beginning of this article?) Stage II is said to bring as much as a 20% bump in power over stock.

Stage III continues building on the previous stages with big-bore cylinders and pistons. The 107 engine grows to 114 cu. in., and the 114 engine becomes a massive 117 cu. in. The end result is about a 30% increase in power over stock. For those who must have it all, Stage IV adds CNC-ported and polished heads to the packages.

All four of the Screamin’ Eagle kits are 50-state legal and do not alter the engine’s factory warranty.

Harley-Davidson has taken a bold move in updating its Big Twin engine and has proved that air-cooled engines can still meet ever more stringent emissions regulations while still meeting the desires of the motorcycling public.

So, by now you’re probably wondering how all of these changes play in the real world. Well, here’s a little teaser before we delve into first ride reviews of specific models in the next few days. First, from the moment the starter is thumbed, the engine sounds different. Previously, when the engine was cranked over, it would struggle to get through the first compression cycle. Now, the engine cranks easily and fires almost immediately. From there, the first blip of the throttle reveals that the engine revs up much more willingly which seems counter to the increased flywheel inertia. Getting under way and while negotiating traffic, the clutch is noticeably easier, but it still requires a firm pull. Regardless, the improvement plays out in traffic.

The 107 engine’s increase in torque is immediately apparent. As we’ve come to expect from Harley EFI, the throttle control is precise, smooth, and without a hiccup, no matter the riding conditions from huffing along at low rpm to aggressive riding. Top gear can even be carried down to below 2,000 rpm (about 40 mph) and rolled back on without the engine protesting – though it pulls cleaner if the revs are kept above 2,000. And that’s just the 107ci engine.

The 114 is the same – only more so! While I did find the clutch a little bit pickier in its initial engagement on the CVO model, any complaints about that faded as soon as the throttle was opened. If you’re the type of rider who likes the stop light grand prix or wants to goose the throttle out of corners, the 114 delivers miles of smiles. Even with the beefier output, the EFI is just as seamless. Finally, the exhaust note is throaty for a stock system, which might make people consider not putting a loud pipe on their bike.

Hang on! More is on the way.

Like most of the best happenings in his life, Evans stumbled into his motojournalism career. While on his way to a planned life in academia, he applied for a job at a motorcycle magazine, thinking he’d get the opportunity to write some freelance articles. Instead, he was offered a full-time job in which he discovered he could actually get paid to ride other people’s motorcycles – and he’s never looked back. Over the 25 years he’s been in the motorcycle industry, Evans has written two books, 101 Sportbike Performance Projects and How to Modify Your Metric Cruiser, and has ridden just about every production motorcycle manufactured. Evans has a deep love of motorcycles and believes they are a force for good in the world.

More by Evans Brasfield

Comments

Join the conversation

Still trying to re-invent the wheel with the antiquated Harley Product? Anyway, thought I'd share my recent article relevant to Harley and the Loud Biker Cult[ure]...see: The Truth about Loud Motorcycles the Police Won't or Can't Tell You: https://rickeyholtsclaw.wor...

Rick Holtsclaw, Houston PD/Retired

William Harley, Arthur Davidson, Walter Davidson and William Davidson have FINALLY all turned over in their graves at the same time. They started to breathe again in 1969 when H-D came a hairs length from folding up, then went back to sleep when AMF saved the decade, but NOW in 2018, all the cemetery dirt looks like a revolution in garden tilling.

NO REAR SUSPENSION that compares with "1903".

NO BALANCING that compares with "1903"(only INTERNAL COUNTER-balancing).

NO AIR for cooling that compares with "1903", we need WATER/OIL BATHING...

SIZE that meet or exceeds factory specs for a hippo, yet cannot keep TRACK with a V-Twin from 1911(no transmissions back then until 1915).

SIZE that has to be air lifted onto any BOARDTRACT(if it is flat).

PAINT that cost an extra 10k!

AND NOW, back to a single CAM, with a camchain that looks displaced from a CADILLAC.

VALVES aplenty in a CHAMBER shaped like a BENT roadsign, unlike ANY OTHER even landed onto this planet!

BUT, the DY-NO says it all- we NOW have MORE TORQUE than ever before!

HELLO, AMF, if you can again RISE, attach the letters H-D to words that MOVE with the birds instead of the blizzards.