Ducati Project 1408 Superbike Leaked

New 1299 Superleggera on the way!

Ducati seems to be ready to launch a new version of its limited-edition halo superbike, the Superleggera, and it apparently comes with some staggering numbers: 220 hp and 342 lbs. Oh, and then there’s the purported 66,000 English Pounds it’s rumored to cost in Europe.

Of course, none of this is actually official. Ducati had launched a web portal that some of its best customers were given access to, project1408.ducati.com, in which some details about a new superbike were released. Inside is information about a spate of new carbon-fiber components that surely must be part of a thoroughly updated Superleggera.

Our media rep at Ducati, Nathon Verdugo, wouldn’t confirm a new Superleggera, but he did allow that, “Ducati is always in evolving its superbikes and we will always be a superbike leader. At EICMA we’re going to deliver our stamp on the superbike world with a sledgehammer.”

A letter Ducati sent to its premium customers states its “engineers have once again created a motorcycle that redefines the boundaries of what is possible, turning a dream into reality.”

Ducati Panigale Superleggera Quick-Ride Review Video

The previous Superleggera, Italian for super light, retailed in America for a heady $65,000 and was rated at “>200 hp.” This new one shares the same 342-lb dry weight but employs carbon fiber in new areas for a production motorcycle.

Most interesting is the carbon steering-head section of the monocoque frame replacing the magnesium frame member of the existing Superleggera. Ducati says this carbon section with 7075 aluminum inserts saves 3.53 lbs over the aluminum component on the regular Panigale, a 38% reduction, but no mention is made of how much lighter it is than the mag piece from the current SL said to weigh 6.6 lbs.

Text says the new carbon bits undergo “MotoGP-standard quality control measures such as Active Transient Thermography, Ultrasonic Phased Array and Computed Axial Tomography” to be sure of its structural integrity.

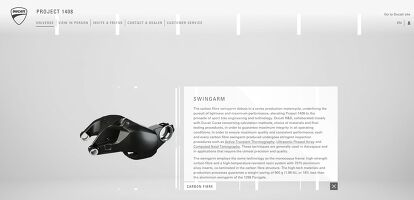

This also applies to the new carbon swingarm, another first for a production bike. It also uses 7075 aluminum inserts to aid structural strength, and it is purported to be 18% lighter (1.98 lbs) than the aluminum unit on the 1299 Panigale.

More carbon is found in the wheels, which are said to weigh a total of 3.1 lbs less than Ducati’s premium forged aluminum hoops. They offer a claimed reduction of rolling inertia by 26% on front wheel and 58% on rear. It’s likely they are sourced from BST.

As for the Ducati 1408 nomenclature, we’re highly skeptical it refers to the size of its engine, as it would be impossible to enlarge the existing 1285cc motor that much. It’s more likely it is part of recent naming conventions since Audi took over Ducati, in which the first two digits are likely the year the project was started, and the second two digits perhaps the number of that year’s bike-development projects.

This new Superleggera will use an uprated version of the 1299’s motor, still less than 1300cc. It will surely be lighter and more powerful than any other production Ducati, something around 220 hp when rated at its crankshaft, and it will have a dual-piped underseat exhaust like the latest Panigale factory Superbike.

“There are some things about this platform that are different from anything else out there,” Verdugo teased. “We are trying to expand our brand and create new riders (with bikes like the Scrambler), but we are at our heart and soul a superbike company.”

Full details will be revealed November 7 at Ducati’s press conference the day before the EICMA show in Milan begins.

More by Kevin Duke

Comments

Join the conversation

I'm holding out for their 1099 middleweight.

LOL

"Look, dear esteemed HNWI customer, here's a login for our TOTALLY SECRET PAGE with TOTALLY SECRET INFORMATION, and we'll TOTALLY SUE YOU if you pass that info to the media, so don't do it, m'kay?"

That's such a ridiculous marketing ploy. You don't show stuff to the general public that you don't want the general public to know. This rather serves two purposes: Give rich people a feeling of specialness, and putting some morsels towards the public with the hint of secrecy and exclusiveness.