Arai: The Philosophy Behind The Helmets

Old world craftsmanship and guiding principles define Arai's thoroughly modern helmets

Big manufacturers rarely open up their factory doors to the inquisitive eyes of journalists, and when they do, it is typically to show off the state-of-the-art nature of their manufacturing process. Recently, Arai opened its factories for a host of international journalists to show how their premium helmets, which are seen around the world on the grids of the pinnacle classes of each respective motorsport category, are as much the product of hands-on craftsmanship as they are technological advancements. The reasoning behind this openness was the desire to show why Arai believes they make the best motorcycle helmets in the world. The tour was enlightening for all who attended because Arai had the opportunity to show how its long-held core philosophy about head protection affects almost every step of the helmet construction process.

MO Tested: Arai Regent-X Review

MO Tested: Arai Corsair-X Review

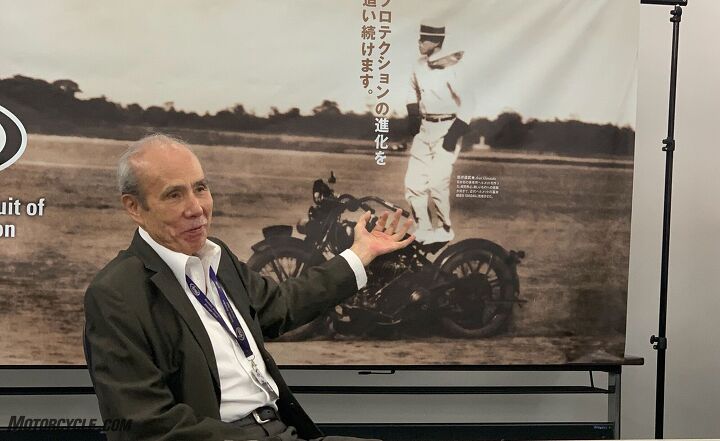

But really, we need to go back to Arai’s entry into the motorcycle helmet business to understand the brand. Hirotake Arai, the founder of Arai, was a motorcycle enthusiast and is the rider in the iconic Arai photo of him standing atop the Harley-Davidson with his hands casually stuck in his pocket – his tie jauntily flapping over his shoulder – as the bike travels across what appears to be a dirt field. Although he was by profession a hat maker, he was also a lifelong motorcycle enthusiast. Perhaps manufacturing things like construction helmets made him aware of the protection he lacked when riding. At the time, there were no motorcycle helmet manufacturers in Japan, and since the country was a closed market, helmets weren’t available from elsewhere. Because of his affinity for motorcycles and racing, Hirotake knew that riders and racers needed helmets. So, he set out to create them. With this act, he started the motorcycle helmet industry in Japan.

Today, Michio Arai, the son of Hirotake, is the President and CEO of Arai Helmets, and at 81 years old, he still finds time to ride motorcycles. Arai is still a family-owned company, which means it is not subject to the whims of shareholders or others who place profits above all else. When Michio met with the assembled journalists in Arai’s Ōmiya factory, he talked of the company’s philosophy on helmet safety, and while the manufacturing process set up at the four Arai factories may not be the most efficient process, he feels it allows his company and its highly trained, dedicated craftspeople to build the best helmets possible.

The thought behind the helmets

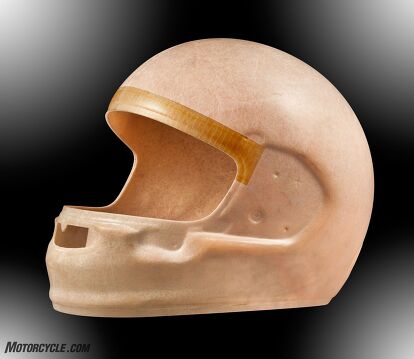

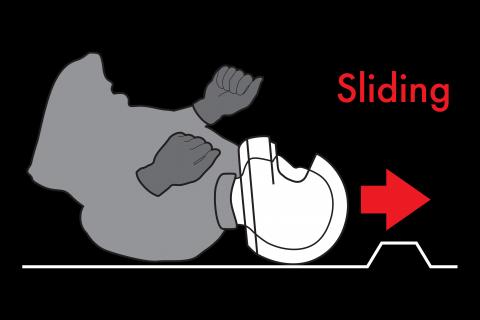

In recent years, much has been made of rotational forces imparted to the brain in some helmet impacts, leading to new technologies designed to manage those forces. Arai, however, claims that it has been managing those forces since the inception of its helmets. Key to this philosophy is the round shape of the Arai shell. Often referred to as being egg-shaped, Arai has codified this design as the “R75 Shape,” which is defined by the radius of the shell being a constant 75mm. Additionally, Arai is committed to avoiding any protrusions or attachments to the exterior that could catch the helmet, but we’ll come back to that later. For now, the operative idea behind Arai helmets is that they are round and smooth.

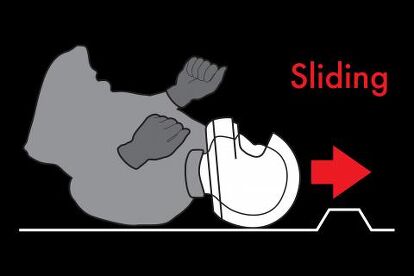

Arai’s reasoning behind the round shell shape is that it allows the helmet to glance off objects rather than hit them solidly. The result of this glancing action is that fewer G-forces are transferred to the helmet, requiring less attenuation of those forces. According to Arai, this is important because real-world impacts can easily exceed the absorption standards set by helmet sanctioning bodies, and Arai designs its helmets to do more than just meet standards. Additionally, when a helmet slides off an object, instead of hooking on it, minimal rotational forces are transferred to the rider. To this end, Arai designs all of its external ventilation features to be stuck on after the final construction of the shell. These external protrusions are quite fragile and will crush or rip off before they could transfer any rotational forces to the shell/rider. Compare this idea to the aero shapes favored by some other manufacturers.

The glancing action isn’t the only way the shell protects the rider. Arai constructs its shell to be exceptionally strong, which directs the forces around the outside of the shell rather than to the interior padding. However, Arai helmets are also designed to selectively crush without failing from impacts as a means of dissipating force. The importance of this, from Arai’s perspective, can’t be overstated. Any force that is redirected or attenuated by the shell keeps the EPS liner from having to absorb it instead. According to Arai, this allows its helmets to not only meet sanctioning body requirements, but also exceed them.

Hand-crafting protection

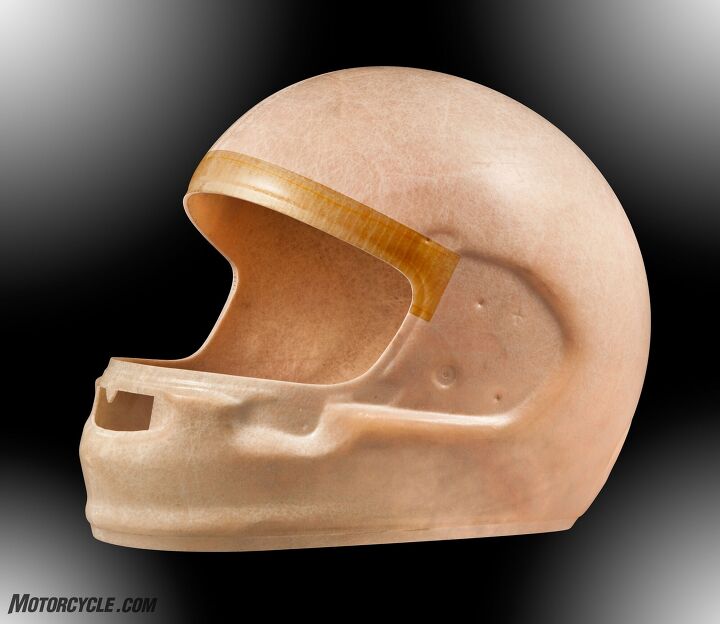

Creating the desired hardness in the shell is a multi-layered process, utilizing several types of high-performance textiles overlaid with each other prior to being impregnated with resin.

The inner and outer layers of the shell are what Arai calls a bird’s nest that is constructed from equal length super fibers that are blown onto a head form. The result of this technique is that the fibers overlay each other randomly, creating an extremely strong, yet compact, matrix that resists cracking when the fibers are infused with resin. Every layer of the shell consists of specially designed fabrics, ranging from felt-like to a super fabric that is specially-woven in house. These additional layers of fabric assist the shell in maintaining its structural integrity in places where the impact has partially crushed it.

To see how this layering of fabric increases protection, the eye-port provides a great example. Since the opening cut for the eye-port creates a weak point on the shell, Arai embeds a special, extremely strong fabric (one that is woven exclusively on-site) in the shell’s matrix across the shell’s brow. Thanks to the stiffness of the shell’s brow, a softer EPS liner can be used here while meeting or exceeding the various impact standards that are in place worldwide.

Before progressing any further, we need to consider the craftspeople who construct Arai’s shells. Arai claims to have a very low turnover rate with its employees, one that is the result of having the workers be invested in the quality of the product. The company trains its employees as they rise up through the system, and ultimately, some rise to the highest rank of Shell Expert. These select people examine each shell at several points throughout its construction, and at key steps during manufacturing, these experts have absolute authority to scrap a shell that doesn’t meet tolerances. For example, each bird’s nest is visually inspected for an even layering of the materials, and if the overlay of textile strands is not optimal or the nest does not meet weight specifications, it is set aside for disposal.

Perhaps the most surprising part of the shell’s construction is the curing step. Here, Shell Experts insert a bird’s nest, followed by all of the other fabric components and the second bird’s nest into a mold that is preheated to 200° F. These craftsmen are sticking their hands and arms into these heated molds without any protection. Additionally, each helmet has its own set of fabric components that must be precisely placed in unique positions for each shell model within a mold. (An example of how skilled these craftsmen are is that each station has multiple molds to be attended to, and they are often constructing multiple helmet models concurrently.) The final thing to go in the mold is a sheet of paper with the specialist’s name on it, giving him ownership over the quality of the product. Then a predetermined amount of a special formula resin is poured into the mold before an air bladder is inserted and bolted to the mold. Once the bladder is inflated, the resin is forced throughout the textile components, compressing them into the thickness necessary for the finished product. Finally, the shell is cooked to complete the initial curing process. Later, these shells will be baked in an oven for several hours to complete the hardening.

Premium finish

While Arai helmets are designed to protect riders from head trauma, these premium helmets are also known for their superior fit and finish. So, preparation, painting, and decal application are the next three steps for each shell. Of course, within these three steps, there are several sub-tasks involved. For example, in preparation for the final color paint coats, the shells start with a filler before the primer coats are applied.

The surface of the shell is not perfectly smooth, and there are occasional gaps between the fibers to be filled. Much like how drywall installers use “mud” to fill in the gaps and screw holes in wall panels, Arai’s technicians use a similar substance to fill in the shell’s surface on a micro level. This mud is rubbed on the shell surface and sanded off once it is dry. Then multiple primer coats and water sanding aid in making a perfectly smooth surface for the paint that will be visible to the end-user. All of this is done by hand because the Arai philosophy is that only humans have the deft touch to sense and achieve the quality of preparation required for the paint.

After the color coat is applied, the decals that form the helmet’s graphics – from the most basic to the most intricate race replica – are applied by hand. This detailed work is done exclusively by women since, according to Arai, they have superior hand-eye coordination and the ability to maintain the focus that is required for the intricate placement of the decals.

With the decals applied and the final clear coats laid down, the shell looks a lot like a helmet, but it’s far from finished. All the holes need to be drilled – by hand, of course – for ventilation and hardware mounting points for the face shield. The rubber gasket around the eye-port is glued in place and checked for proper sealing with the visor. Finally, the air intake and exhaust ports are mounted with double-stick tape.

In the past, we’ve heard people complain about how delicate the venting structures on Arai helmets were in the case of an accidental bump or drop. Rather than being the result of cheap manufacturing, this is a design feature of the helmet, assuring that any structure that is affixed to the R75 shell either crushes or tears free in a crash.

The helmet interior

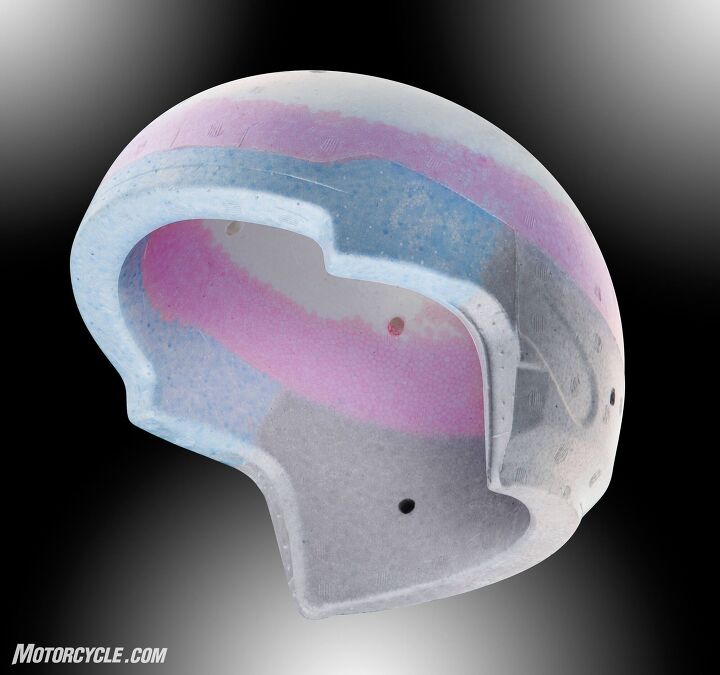

Throughout the bulk of this article, we’ve focused on the helmet shell and the complex assembly process. With the EPS liner, things will be a little different. Unlike many other helmet manufacturers who use multiple pieces of EPS to tune the liner’s compressibility, Arai uses a one-piece variable-density foam liner where pellets of different density EPS are fused together into a single piece. Since this is a proprietary process, Arai didn’t show it to the assembled journalists. Bummer. Still, Arai has been at the forefront of utilizing EPS in motorcycle helmets since the 1950s, when it (unbeknownst to and virtually simultaneously with Bell Helmets) first used the foam to absorb the G-forces of head impacts.

Helmet interiors are more than just EPS, though. Arai takes it’s comfort liners very seriously. Since riders sweat, the liner wicks the moisture to keep the helmet as comfortable as possible. Should it develop a funk, it is removable for cleaning. However, the liner also plays a role in the quietness of a helmet. Special pieces of foam are cut to conform to the rider’s face and head shape to help block road noise. The cheek pads use Arai’s Facial Contour System to allow easy entry yet a snug fit once the helmet is in place, requiring an intricate collection of foam shapes and densities to assure this fit. Anyone who has ever worn a bargain-basement helmet before moving up to a premium model knows that, while they may pass the same certification testing, the attention to fit is instantly appreciable.

Proof of concept

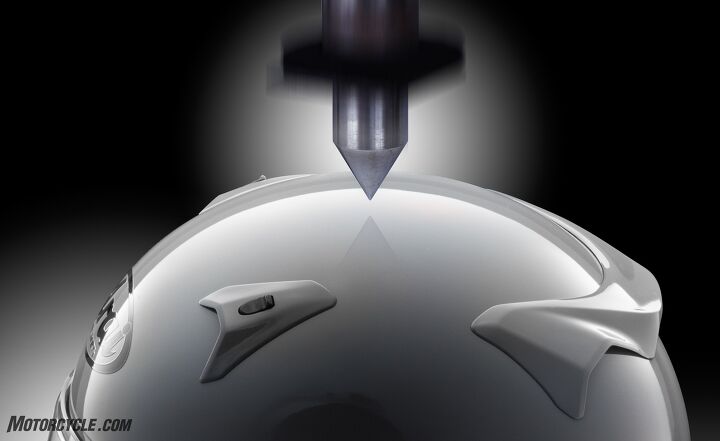

After touring Arai’s four factories, we journalists were able to witness a demonstration of how a finished helmet withstands impacts. Repeatedly throughout the tour of the factories, we were told that Arai helmets were designed to not just meet but exceed the impact specifications required by various sanctioning bodies. Using a guided drop of a certified head form onto an anvil as described in the Snell-M2015 testing standard, Arai allowed the journalists to see the results with their own eyes. The Snell test consists of two drops, the second one being slightly lower as a simulation of a rider tumbling and losing speed in a crash.

Get the Flash Player to see this player.

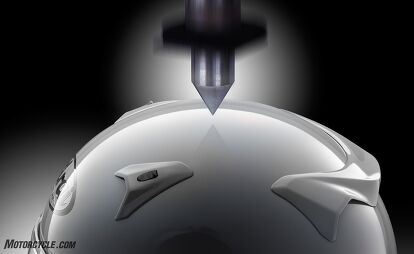

According to the printouts of the tests, the first drop was from a height of 322 cm (10 ft. 7 in.) and delivered a peak g-force of 182 g, well below the Snell limit of 275 g. The second drop was from 250 cm (8 ft. 2 in.) onto the same spot on the helmet, yielding the same 182 g registered within the head form. Impressive. The final demonstration was the penetration test (done to the FIA 8860 standard), which tests whether a cone-shaped rod dropped from 486 cm (15 ft. 11 in.) can be stopped by the helmet before it completely penetrates the EPS liner. To make the test even more challenging, the rod was directed towards one of the vent holes drilled in the shell.

Reading about and understanding these tests can’t prepare you for witnessing them test firsthand. The sound of the impacts is mind-boggling, and seeing the helmet punctured by what is essentially a heavy steel arrow is both harrowing and heartening, knowing that the tip never made it through the EPS.

The takeaway

Spending two days touring four factories, with some motorcycle rides in between (including one epic rain) is a lot to digest. In the end, though, the overriding impression I received from the experience was that Arai takes protection very seriously. The company has created a manufacturing process that sacrifices efficiency in the name of quality control and premium construction. Proof of this comes from the fact that world champion, Arai-sponsored racers’ helmets only differ in graphics from the helmets that you or I could buy from our local dealer. We get the same protection as the best-of-the-best. This is the result of dedication from the top down, a devotion to evolutionary design changes based on core principles, created by highly-trained craftspeople who are invested in the product of their labors.

So, when you put on a new Arai helmet for the first time, remember that as many as 40 other people have most likely laid hands on it during the construction process. Arai has always had a reputation for creating premium helmets, and that is the result of a guiding philosophy handed down from the original owner to the present.

We are committed to finding, researching, and recommending the best products. We earn commissions from purchases you make using the retail links in our product reviews. Learn more about how this works.

Like most of the best happenings in his life, Evans stumbled into his motojournalism career. While on his way to a planned life in academia, he applied for a job at a motorcycle magazine, thinking he’d get the opportunity to write some freelance articles. Instead, he was offered a full-time job in which he discovered he could actually get paid to ride other people’s motorcycles – and he’s never looked back. Over the 25 years he’s been in the motorcycle industry, Evans has written two books, 101 Sportbike Performance Projects and How to Modify Your Metric Cruiser, and has ridden just about every production motorcycle manufactured. Evans has a deep love of motorcycles and believes they are a force for good in the world.

More by Evans Brasfield

Comments

Join the conversation

My old Arai, I think it was a Vector 2, has been my favorite helmet. When I put that thing on, it felt like I was wearing a tuque!