Ask MO Anything: Why Do We Still Use Camshafts?

Dear MOby,

Why are camshafts still used? I’d think that valves could be controlled by small electronic controllers and be directed to open and close with much greater accuracy (as well as being more “condition-dependent”) than the generally fixed operation they follow based upon a cam profile.

In addition to more precise control, it would probably be lighter and have minimal or no spinning kinetic energy to take account of. Probably also provide engine packaging advantages as well.

And changes would be much easier/quicker to make and test – no need for casting a new cam to test how profiles might work. And, it could obviously tie in with the motorcycle’s ECU, IMU, and any other “U’s” for even finer granularity of the functions it provides.

Walter

(Walter asked this in Comments after Ask MO Anything three weeks ago, in which we explored whether the IMU [inertial measurement unit] actually serves a useful purpose.)

Evans Brassfittings actually came up with the answer to this one immediately: It’s called the two-stroke engine. You don’t have to search much to stumble across things like Arctic Cat’s new 6000 C-Tec2 direct-injected two-stroke on our sister site Snowmobile.com, where our friend Jerry Bassett writes “modern and evolving direct injected two-stroke technologies led by companies such as Rotax, Evinrude, Orbital of Australia, Synerject in the US and others can point to the fact that two-strokes can be as emission friendly and miles per gallon efficient as four-strokes.”

BRP (Bombardier Recreational Products) introduced its E-TEC technology in Evinrude outboard engines in 2003 (and won the Clean Air Technology Excellence Award from the U.S. Environmental Protection Agency), then later adapted E-TEC for Ski-Doo snowmobiles. Its latest E-TEC 800 two-stroke Twin (2010) makes around 160 crankshaft horsepower. Meanwhile the latest 800 H.O. two-stroke Twin Polaris put in two of its sleds for 2015 also makes around 160 horses. Correct, the same Polaris that owns Victory and Indian.

Reading between the lines of the reviews, it seems like the finickiness of some of these engines has been or is being worked out, the biggest one being that they’re pretty thirsty. On a snowmobile, though, my very limited experience is that you’re at WOT a lot more than on a motorcycle (except when you’re on a racetrack). Anyway, it’s interesting to contemplate an engine like this in a 400-pound sportbike, but I’ve only met blank looks anytime I’ve brought up snowmobile engines at Victory affairs.

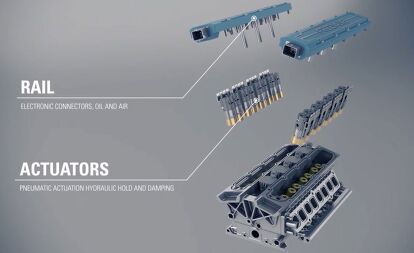

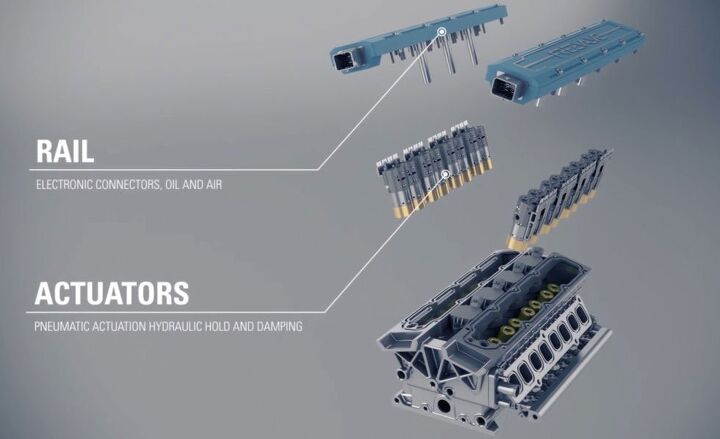

If you must have four strokes and good old-fashioned poppet valves, Walter, we did bump into this Koenigsegg Freevalve video on the www, illustrating a camshaftless head design the Swedish supercar maker has been working on for over a decade.

Though the Freevalve engine retains vestigial valve springs like the ones on a Desmo, actual valve events are controlled by electronically actuated pneumatic and hydraulic systems, meaning there’s virtually no limit to this engine’s ability to customize valve timing for any combination of rpm or load – or shut off cylinders at cruise, etc.

How close is it to production? Close enough to take a Jalopnik reporter for a ride in a Saab equipped with the Freevalve engine a couple years ago. Anyway, nothing is new under the sun, and camless technology is a thing many manufacturers have been experimenting with for years. Good old Wikipedia is a good place to start investigating if you need to know more.

Direct your motorcycle-related questions to AskMoAnything@motorcycle.com, though some say we’re better at non-motorcycle-related ones…

More by John Burns

Comments

Join the conversation

Thanks for the follow-up.

So: a bit more power, a bit better economy, and lowered emissions. Not mentioned is the weight savings removing the cams, belts, gears, etc. (not such a big deal for a car, but more important for a bike). Power consumption seems a bit high,and durability is still unknown. But hey, early FI had some issues that needed to be worked out before it became as good as it is. So I remain optimistic that it is probably just waiting for the right breakthrough.

Thanks again.

I noticed that the article didn't answer or even address the question of why we still use camshafts? The short answer is that camshafts are currently the best solution to valve actuation.