Ask MO Anything: Buell Blast Keeps Breaking Engine-Mounting Bolts

ROTFL or RTFM?

Dear MOby,

This is the email we got:

Breaking head bolts that go through the isolator mount 2 the top of the head on the engine block I’ve already replaced them like four times I torqued it to Harley recommends 90 I Torked it to like 60 because of the aluminum head do you have any suggestions for this problem I have a 2003 Buell Blast thank you for your time

We translated it as:

The head bolts that go through the isolator mount to the top of the cylinder head on my 2003 Buell Blast keep breaking; I’ve replaced them like four times. Harley recommends torquing them to 90 ft-lbs, but I torqued them to about 60 because of the aluminum head. Do you have any suggestions for this problem? Thank you.

Sincerely,

Jason Jones

Florida

Dear Jason,

Is it just me, or are most AskMO questions about Buells lately? We passed your question on to our man Chaz Aagaard, of Aagaard Moto Foundry fame in Janesville, Wisconsin – where Buells are a specialty.

Chaz says:

“Well, the answer isn’t under-torquing them, that’s for sure. My questions include: Are these H-D (Buell) fasteners of the correct length and grade? Are we following the install procedure, and are all the bolt holes in the head in good shape, or ovaled out? Are both the front and rear isolators new and in good shape? The answers to all those questions need to be yes before proceeding.”

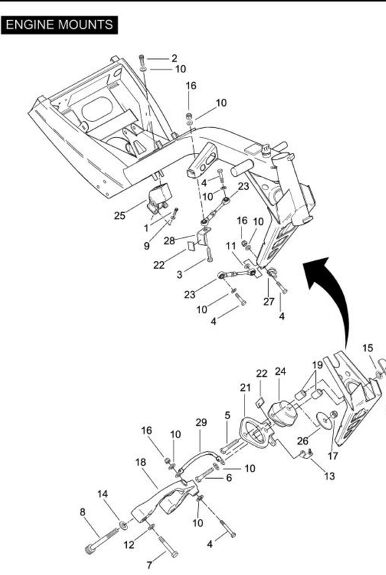

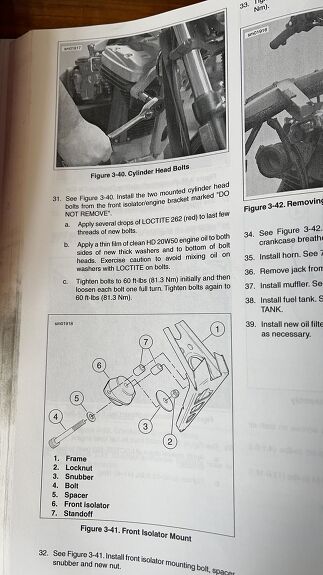

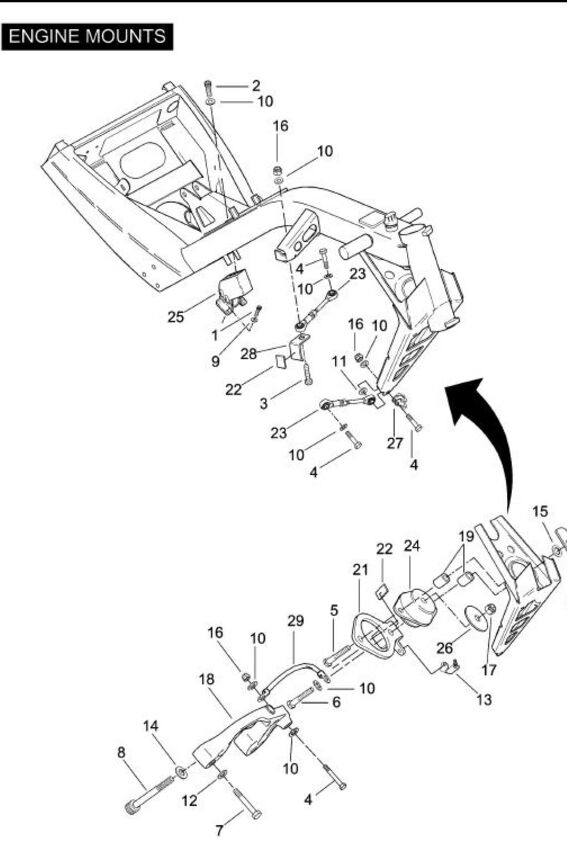

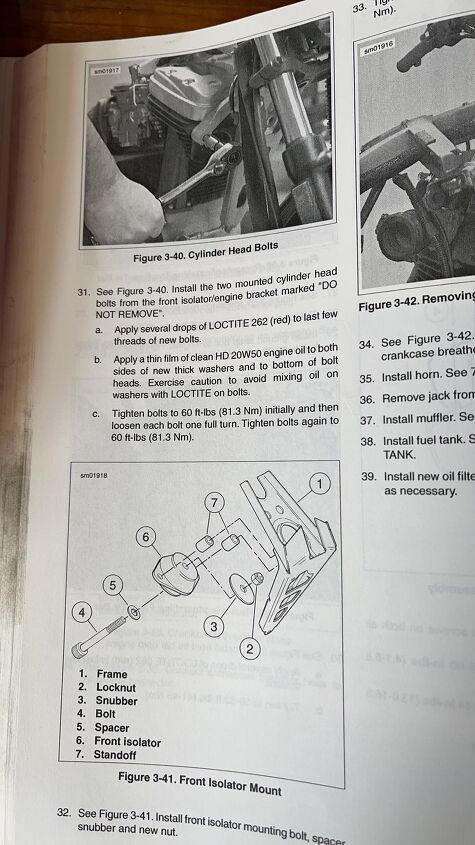

Chaz was kind enough to send along a couple pages from the manual:

There are quite a few parts in the “system” Buell came up with to isolate that 492 cc half-a-Sportster engine’s vibrations from the rest of the motorcycle, and they all need to be put together by the book for the package to hang together as intended. By “the book,” we mean the factory manual, which so many times has the answers when it comes to these kinds of problems.

Congratulations, you were doing the right thing by torquing to 60 ft-lbs, but were you doing it as the manual specifies, with oily washers and red Loctite? Agreed, that is one of the weirdest instructions we’ve ever seen, which tells us the Buell people must’ve been experiencing the very same problem all those years ago that you’re learning about now, before they came up with a way to fix it – for 18 years, anyway. Like the banana in the famed song, the Blast engine-mounting bolt must be tightened in a certain way.

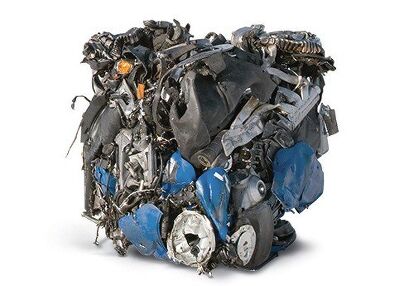

Hats off to you for preserving a piece of history, even if it is an old piece of entry-level motorcycle history that received a fair amount of opprobrium from not just the press, but even from Erik Buell. Harley insisted it needed a beginner bike at the time and assigned the task to Buell, but it was never established that Buell’s heart was truly in the Blast project, given H-D’s parameters.

Then again, maybe the Blast was just ahead of its time? Today, it looks a little bit like a cross between a KTM Duke 390 and a Grom, which means it might’ve been somebody if it had come out in our current era of lowered expectations instead of in the middle of the sportbike boom. In any case, the Blast deserves better, and there are a few very cool modified Blasts running around out there.

When you eventually do move up the food chain, Jason, the Blast will have taught you valuable lessons. Like this one it just taught all of us. Oil those washers with HD 20W50, and RTFM!

Direct your motorcycle-related questions to AskMoAnything@motorcycle.com, though some say we’re better at non-motorcycle-related ones…

More by John Burns

Comments

Join the conversation

The bolts attaching the bracket to the head are unique, with special threads that make more contact with the threads on the head. Using the wrong bolts, especially of a lower grade could cause them to break.

Also, that bracket has the words "DO NOT REMOVE" stamped into it. Only remove it if necessary, for example when using some types of valve spring compressors. Also, don't use an aggressive thread chaser on the holes in the head, as the threads on it are not quite standard.

Also yeah, the front isolator/motor mount is known to have problems with durability, and once it wears through, other things start to break.

Hope this helps someone.

-Rat King Moto, proud owner of a "very cool modified blast"

As someone who unintentionally ended up as one of the Internet's authorities on Blast maintenance -- Rolling Physics Problem continues to get more hits on my Blast repair articles than almost anything else I've written -- I have a bit more nuanced view.

The Blast was a really fun motorcycle when it was running well -- on paper, the bike is really close to the specs of... wait for it... a Vincent Comet -- but a few short sighted manufacturing decisions really made them hell to keep in the zone. If the bike had a different method for attaching the carb -- bolting something (ANYTHING!) solidly to something else -- a better rubber intake manifold, a better stock exhaust, and didn't have the ridiculous auto choke/ignition advance system, which made a reasonable carb into a terrible one -- occurring as it did at the end of carburation and before FI was a thing -- people would not go first to ridicule when someone says 'Buell Blast'.

The motor mounts, sadly, didn't help either -- https://rollingphysicsprobl...

After this little imbroglio, I put my youngest son on a CB500F. ;-)