Suzuki Factory Tour Part 2: Takatsuka Engine Manufacturing Plant

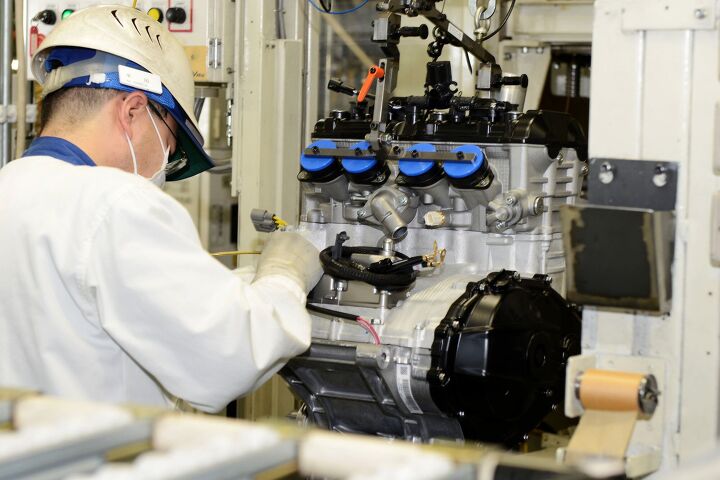

Watching GSX-R1000 engines being built by hand in Japan

The all-new 2017 GSX-R1000 is “a huge impact model for us,” Takeshi Hayasaki, president of Suzuki Motor of America, told us at the Gixxer’s launch earlier this year. As such, part of the new GSX-R’s media launch included tours of Suzuki’s three main facilities in Japan where we could witness the care and precision that goes into each bike’s development and its production.

Suzuki Factory Tour Part 1: Ryuyo Test Facility

First off was a trip to the Ryuyo development complex you can read about in the link above. Our next stop was the Takatsuka engine plant in the Shizuoka prefecture where crankcases, crankshafts, cylinders and heads are mated and and assembled prior to their installation in Suzukis built at the Toyokawa production facilities located about 30 miles away.

Fun Fact: The Suzuki Loom Works, a textile company, was established in 1909. Suzuki’s first motorcycle, the unfortunately named Power Free, debuted in in 1952.

The engine factory at Takatsuka consists of nearly 2 million square-feet on a facility sprawling over nearly 10,000 acres. Amazingly, the factory is staffed by just 264 employees that operate 28 production lines. Four lines are dedicated only to crankshaft production, and each can produce 200 cranks a day.

Fun fact: Suzuki’s workforce consisted of 15,000 employees in 2016. About 91% of Suzukis are sold overseas.

Engine production is segmented into three areas: 250-1000cc Twins; 50-650cc Singles and Twins; and 250-1800cc four-cylinders, Twins and Singles, including the GSX-R1000, M109R and Hayabusa. Suzuki tells us that it typically takes 90 minutes to build a four-cylinder engine and it requires 90 minutes to change a line to another model. One line at Takatsuka is dedicated to the GSX-R1000 engine, and up to 200 Gixxer Thou engines can be produced each day.

I could’ve spent an entire day watching the phenomenal precision and efficiency of workers assembling engines at the Takatsuka facility. Come along for a walk-through of the factory to see GSX-R1000 engines being built in the pictures and captions below.

And that’s the end of the line, at least as far as we have pictures to illustrate the process of building the GSX-R1000’s impressive engine. Stay tuned for our tour of the Toyokawa factory where Suzukis are assembled and prepared for customers around the world.

More by Kevin Duke

Comments

Join the conversation

They should have used a TFT dash on K17 Gixxer.

Next years model should have showas electronic suspension for higher spec model.

Another fascinating look behind the scenes. I look forward to the next installment.

Did your hosts talk at all about their production management methodology? My company has adopted much of Toyota's processes and techniques, like 5S, QCPC, etc. Its remarkable how advanced Japanese manufacturers were in this area over the US at one point.