Honda in America

Celebrating 60 years of history in the U.S.

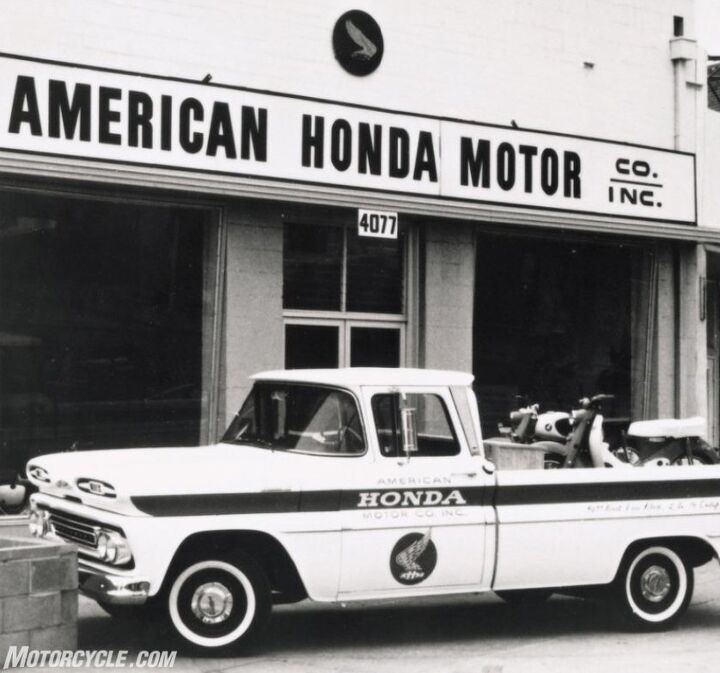

It’s interesting to me that a Japanese brand like Honda can feel, at times, just as American as apple pie and baseball. The brand has played an integral role in not only motorcycling, but industry in general in America since the `60s. In fact, this year Honda celebrates 60 years since a small storefront in Los Angeles opened its doors in 1959 as the company’s sole U.S. business operation.

Motorcycle.com was fortunate enough to receive an invitation to a static unveiling of the 2020 Honda Africa Twin in Ohio the weekend of AIMExpo in Columbus. The real treat of the trip though, since we weren’t able to ride said 2020 Africa Twins, would be our visit to the Honda Heritage Center, Honda’s Marysville manufacturing facility, and the Transport Research Center, all of which sit close together in a part of Ohio affectionately referred to as Hondaland.

It’s clear to see that the Japanese company has invested heavily into its operations in America throughout the years. Honda has 75 facilities across the United States that range from manufacturing, R&D, parts centers, and sales, marketing, service, and finance operations. Those facilities employ more than 31,000 associates nationwide. Three-quarters of that number work in manufacturing roles like those found in the Marysville facility that we were able to tour while in Ohio. And, speaking of Ohio, Honda also happens to be the largest manufacturing employer in the Buckeye State. The company has invested significantly into its presence in central Ohio.

Although Honda ceased production of motorcycles in the U.S. in 2011 as the last Honda Gold Wing rolled off the Marysville assembly line, motorcycling is still deeply ingrained in the company’s American roots. We were able to get a look into the past at the Honda Heritage Center.

When American Honda opened up shop in California in 1959 with eight employees, it began selling motorcycles only and, in just under 10 years, in 1968, the company celebrated the remarkable milestone of one-million Honda motorcycles sold in America. Shortly after, Honda began importing automobiles into the States and nine years later opened its first manufacturing facility in Marysville, Ohio. What was the first machine to roll off the line? None other than the iconic Honda Elsinore. Just a few years later the same manufacturing facility began production of automobiles and in 2018, Honda celebrated its 25 millionth automobile made in America.

The Honda Heritage Center, which is free to visit, does a great job of highlighting the company’s achievements over the last 60 years with interesting exhibits and displays that tell the Japanese company’s history in America.

Stepping into the four million square-foot Marysville automotive plant, all of the nostalgia of the museum quickly fades as you watch building-sized presses stamp rolled metal into car shapes next to assembly lines of robotic arms lifting entire frames and welding them together. Employees zoom around on personal mobility vehicles of all sorts, some pulling long tails of carts containing doors, glass, and other crucial componentry of whatever’s pumping off the line that day.

Having the chance to tour the inside of a major automotive manufacturing plant gives an interesting perspective to the scale of the operation. After having toured Italian motorcycle manufacturing facilities as well as American motorcycle factories, nothing holds a candle to the complex efficiency of Honda’s Marysville plant. Though it can seem like organized chaos from an outsider’s point of view, it would be unfair to call it such. Organized yes, but chaotic, not in the least. The facility is a brilliant example of the mesh between Japanese efficiency and hard-working salt-of-the-earth Midwesterners that have been building Honda products here in Ohio since 1982.

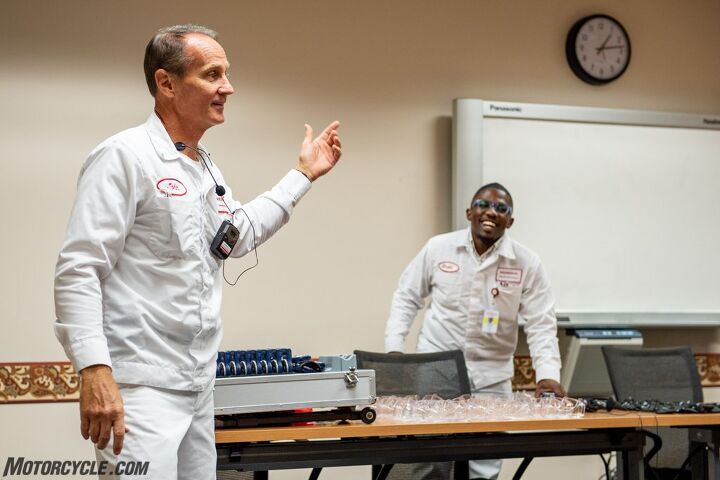

Tours of the plant are available free of charge. You only need to register in advance and pick a time and date. I highly suggest taking the tour. Our guide provided insights to what was going on around us as well as facts about the culture of working for Honda and some of the history of the facility itself. After walking what we were told was about a mile during our plant tour, we headed off to check out the TRC, a facility which is apparently shrouded in secrecy and somewhat difficult to score a tour of.

The Transportation Research Center (TRC) sits on 4,500 acres of Honda-owned land near the Heritage Center and Marysville plant. Although Honda owns the land, the TRC itself is a separate entity. The Traffic Research Center provides proving grounds for countless different tests for all sorts of two- and four-wheeled vehicles. In fact, the TRC is the largest independent vehicle testing facility and proving grounds in the U.S.

“With approximately 4,500 acres of road courses, wooded trails, a 7.5-mile parabolic oval test track, 50-acre Vehicle Dynamics Area, or “black lake,” and the right mix of testing areas and facilities to make the Transportation Research Center Inc. (TRC) in East Liberty, Ohio, the best place to test and validate nearly any vehicle imaginable, any time of year.” – Transportation Research Center

The TRC is specifically designed for stress testing vehicles. Open to all manufacturers, the center provides independent testing services for OEMs and others to gather data from a myriad of testing areas. They also allow clients to come in with engineers and personnel to run their own tests, and even to rent out certain areas when secrecy is of the utmost importance while testing new models.

From the TRC’s mouth: As an independent vehicle test facility and proving ground, TRC is a one-stop source for research and development, as well as compliance and certification testing for vehicles and components. We perform crash testing, emissions testing, dynamic and durability testing, validation; offer specialized test equipment and calibration services, crash dummy rentals, performance and vehicle test driving; host special events and, most importantly, provide engineering solutions.

This is where the automotive industry performs thousands of hours of testing and development of new products and technology. Behind the well secured gates of the TRC, groundbreaking new tech will begin to see the light of day and real-world testing. There is a lot of world-class research being done at this unassuming plot of land south of East Liberty, OH. It was a pleasure to have had the chance to peek behind the scenes.

Honda’s cumulative capital investment in the United States tops $21.1 billion. In 2018 Honda spent $40.8 billion with U.S. companies. It employs 31,000 associates across 75 facilities and has had the longest U.S. manufacturing presence of any international automaker in America. Honda’s investment in our country is impressive and appreciated. Thanks, Mr. Honda for taking the chance all those years ago.

Ryan’s time in the motorcycle industry has revolved around sales and marketing prior to landing a gig at Motorcycle.com. An avid motorcyclist, interested in all shapes, sizes, and colors of motorized two-wheeled vehicles, Ryan brings a young, passionate enthusiasm to the digital pages of MO.

More by Ryan Adams

Comments

Join the conversation

Never thought of Honda as anything but a Japanese company. Nothing wrong with it being a Japanese company. Same with Kawasaki, Suzuki and Yamaha. There's a certain design/engineering ethos too that's different and should be celebrated on it's own. Calling it American is praising it with faint damning.

My job allows me to visit large manufacturing centers. They never fail to impress.

Speaking of Japanese business models: I work for UTC (a big conglomerate). We use a business process called "ACE," which is openly based on Toyota's "lean" business and manufacturing practices. The Japanese deserve a lot of credit for influencing how manufacturing is done world-wide.