Canbus And Motorcycles

What is it? And why should I care?

If you’re curious what technology you might expect to see on motorcycles of the future, look no further than the cars of today. From anti-lock braking systems to traction control and variable valve timing, nearly all the tech we’re ogling over on today’s motorcycles originated on cars 20 years ago. Or more. By now the trickle-down effect of that technology is such that even your basic commuter car already incorporates it.

Another example of this trickle-down tech we’re starting to see on today’s motorcycles is the CANBUS system. We give a lot of attention to tech when it makes the motorcycle faster or safer, but there’s not much fanfare over the electronic infrastructure some OEMs are using to allow all of these subsystems to work together. Finally, electronic engineers, your moment to shine is now. Here’s a quick look at CANBUS and how it’s used on motorcycles.

The Beginning

Before we begin, you should know this is by no means an exhaustive or comprehensive history and outline of the CANBUS network, but rather a quick overview of what it is and why you should care.

The story starts in the early 1980s when Bosch developed the protocols for the CANBUS network. A decade later, the auto industry started to adopt it as the standard for cars going forward. Fast forward again to the early 2000s and BMW are credited with being the first manufacturer to incorporate the tech on two wheels.

But that still begs the question: What is CANBUS anyway?

An Overview

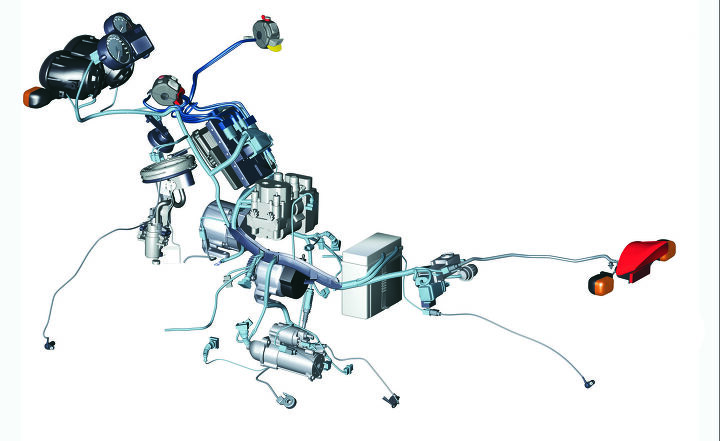

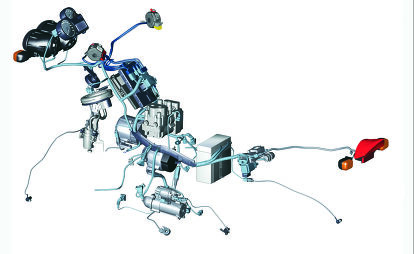

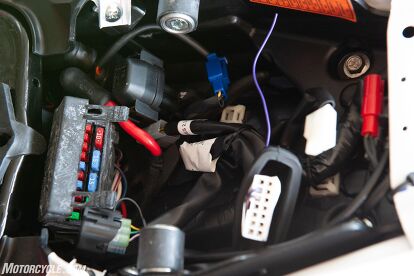

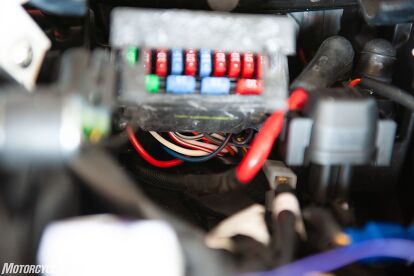

Traditionally, a motorcycle’s electronic system starts at the battery, and any component relying on power would be wired to it. A fuse box would stand between the component and the battery to protect both elements from damage in the event of a spike in resistance, with a blown fuse being the last sacrificial element in keeping everything safe.

As motorcycle tech keeps advancing, this point-to-point wiring system gets increasingly complex and bulky. Nonetheless, many new motorcycles on the road today still rely on this system. One of the benefits some would claim is that, should a failure occur to a subsystem, you can often trace its path of power back to a blown fuse. Simply replace it and you’re back in business. However, critics would say the effort to sort through the bigger and bigger mess of wires is a hassle, and you won’t necessarily know what the issue is every time until you track down the wiring.

The term CAN (Controller Area Network) BUS refers to a network protocol, usually with a central computer – separate from the motorcycle’s ECU – acting as the central communication hub between all the other subsystems. By subsystems, we’re talking about everything from the headlights and turn indicators to the engine management system and ABS. In short, everything.

A CANBUS data network can be thought of like the human nervous system. At the top we have our brain. The brain sends signals through a central channel (the nervous system) to various parts of the body to do something. The same is true for the CAN network. The central computer is the hub and a single wiring harness is the nervous system connecting the computer to the subsystems, allowing them to communicate and “do something.”

Since there’s a single wire harness different functions can piggyback on each other, meaning one wire can perform multiple tasks, reducing the amount of wiring needed compared to a conventional point-to-point system. All of the various subsystems have their own micro computer command stations that are constantly talking back and forth with the central computer to monitor everything. When there’s a failure, the central computer automatically shuts down that particular system, eliminating the need for a fuse box. Instead of having to hunt down wires to narrow down the issue, some sort of error code (or message, or light) will be displayed on the dash. This is what is meant when people say their dash is “throwing a code.” A code reader can then tell you what the problem is.

But There’s A Problem

This is where things get tricky for the CAN protocol. The central computer is programmed to accept a certain power draw or resistance from each subsystem. Sometimes, when you modify your motorcycle, you’ll change those readings. This confuses the computer and sometimes leads towards improper operation of the part and/or error messages popping up on your dash.

A common example of this is your lighting system. On motorcycles with incandescent headlights, it’s common to upgrade to LEDs. Since LEDs draw much less power than incandescent bulbs, the central computer doesn’t recognize the LED resistance and throws a code. Similar issues apply, say, if you were to add heated grips.

You may also notice some touring bikes have a weird charging port that looks similar to a 12v/cigarette lighter, but is slightly smaller. This DIN port is not only annoying as it requires a special charger, but on motorcycles running CANBUS you also need a CANBUS-appropriate charger so the computer recognizes (and is happy with) the power draw being used.

The Fix

So, what do you do? There are a few options. One way is to bypass the computers entirely and wire whatever accessory you want to use directly to the motorcycle’s battery. The obvious problem here is the risk of draining your battery if you forget to turn the accessory off. Alternatively, there are aftermarket manufacturers making CAN-specific accessories that play well with the CANBUS system. In the case of the headlight example above, there are CAN LED headlights that are direct replacements for the stock units. The catch is that, in order to be CAN compliant, they draw the same amount of power to keep the computer happy, eliminating the advantage of LED lights in the first place.

Another option is to use third party CAN bus controllers – assuming one is available for your motorcycle. Typically these plug into the diagnostic port and send the proper signals to the primary CAN computer. Your accessories will then plug into it, and sometimes are able to be activated with the existing buttons on your motorcycle for an extra clean look.

Got It?

Starting to make sense? Well, it took us several read-throughs to make sense also. A lot of people, us included, are mystified by electrical systems on our motorcycles, especially when the spaghetti of wires under there gets increasingly larger and more daunting. For what it’s worth, there’s still a large number of new motorcycles sold today with a traditional fuse box, but it’s reasonable to expect the tide to turn as more tech gets loaded onto motorcycles of the future. So, it’s best to get a better understanding of it now.

The irony is that the automotive industry is already exploring the next generation of data protocols, potentially making CAN tech obsolete on four wheels while it’s still in its infancy on two.

FAQ

What is a CANBUS system?

The term CAN (Controller Area Network) BUS refers to a network protocol, usually with a central computer – separate from the motorcycle’s ECU – acting as the central communication hub between all the other subsystems.

What is CANBUS on BMW motorcycles?

CANBUS on a motorcycle serves the same functions as it does on automobiles. A CANBUS data network can be thought of like the human nervous system. At the top we have our brain. The brain sends signals through a central channel (the nervous system) to various parts of the body to do something. In the early 2000s, BMW is credited with being the first manufacturer to incorporate the tech on two wheels.

Where is the CANBUS located?

The CANBUS is typically part of the wiring harness with connectors attaching it to the various subsystems of the motorcycle (think ABS, ECU, and just about everything else controlled via electricity).

Become a Motorcycle.com insider. Get the latest motorcycle news first by subscribing to our newsletter here.

Troy's been riding motorcycles and writing about them since 2006, getting his start at Rider Magazine. From there, he moved to Sport Rider Magazine before finally landing at Motorcycle.com in 2011. A lifelong gearhead who didn't fully immerse himself in motorcycles until his teenage years, Troy's interests have always been in technology, performance, and going fast. Naturally, racing was the perfect avenue to combine all three. Troy has been racing nearly as long as he's been riding and has competed at the AMA national level. He's also won multiple club races throughout the country, culminating in a Utah Sport Bike Association championship in 2011. He has been invited as a guest instructor for the Yamaha Champions Riding School, and when he's not out riding, he's either wrenching on bikes or watching MotoGP.

More by Troy Siahaan

Comments

Join the conversation

CANBUS in motorcycles in motorcycles is not something new. It's been in BMW motorcycles for over 16 years. My old 2005 BMW R1200RT used it and I had minimal trouble with it with the only real issue being a shutdown of the horn circuit if it was pressed for more than a second. The controller was shutting it down because it thought it was overloaded. I fixed it by putting one of the horns on a relay to the battery with the horn lead controlling the relay. I had that bike for nearly 14 years and put 130 thousand miles on it with no other electrical issues. I also do my own maintenance. The real purpose of CANBUS is to reduce the amount of wiring needed in the vehicle, not eliminate fuses. Instead of individual wires for everything you have controllers that handle various parts of the bike such as the rear tail lights, rear turn signals, etc. The signals for each are multiplexed onto a bus to a controller which then breaks things out to the devices. You have way fewer long runs of wires and fewer things like relays. In my experience on my bikes (BMWs), it has made the electrics more reliable and requires less maintenance. BMW has made some changes in the newer models since my old RT. There are now some fuses (my 2019 R1250RT) whereas on my old 2005, there were none taking away some control of circuit overload from the computers.

As I started working on street bikes with more complicated harnesses, I started hating the old way. I would not be opposed to this new technology, if there was manufacturer agreement on a universal system - so that we all only had to purchase 1 code reader to service all machine brands.