Custom Fit Bell Star Carbon

The new frontier in motorcycle helmet comfort and technology?

Comfortably snug. It’s the idiomatic expression oft used to best describe the way in which a helmet should properly fit. Defining or explaining exactly what comfortably snug feels like, especially to a virgin motorcyclist, is difficult at best. Even many seasoned motorcyclists wear a helmet of incorrect size and/or fitment. But a helmet’s effectiveness largely depends on it being correctly sized and fitted, making helmet choice a paramount decision.

Best New Product: Bell Helmets Transitions Faceshield

In an effort to produce a better-fitting helmet Bell has actively been pursuing a way in which to individualize helmet fitment by customizing the helmet’s expanded polystyrene (EPS) liner. We visited Bell’s hospitality booth at Laguna Seca during the World Superbike race to learn more about the technology Bell is employing to bring this new level of helmet customization to the motorcycling masses.

Inside a darkened trailer above Seca’s front straight we strained to hear Bell’s Advance Concepts Director, Chris Pietrzak, explain the details of its proprietary, 3-D imaging program above the screaming wail of accelerating superbikes. There wasn’t much to ascertain, however, as Bell has multiple patents pending on the technology and was understandably reticent to divulge its company secrets.

HJC Launches New Helmets For 2014

What we do know is that Bell has already committed two years of development leading up to this point of limited consumer introduction and that each custom helmet meets DOT and Snell certification. “We have a very repeatable process that they’re (Snell and DOT) comfortable with as far as being able to always produce the same helmet,” says Pietrzak.

One item of information we heard repeatedly is that the customizing process never removes EPS from the helmet but instead adds EPS. This seems to discount the idea that Bell is taking a standard EPS liner and laser cutting it to fit a rider’s head, but rather that the company might be 3-D printing each custom EPS liner.

But without further empirical data from Bell to report, we sat through Bell’s quick and painless customizing/sizing process, then recently wore the custom Star Carbon to put Bell’s comfort claims to the test. Here’s what we found.

The process begins with information gathering via paperwork and an interview meant to infer details such as how you ride, how you like your helmet to fit (loose, snug, tight), as well as other intricacies so the Bell team can associate the helmet’s fit with your personal riding style (I asked for better vision when riding in a tucked position on the track).

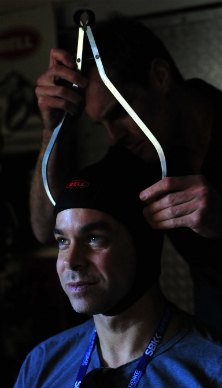

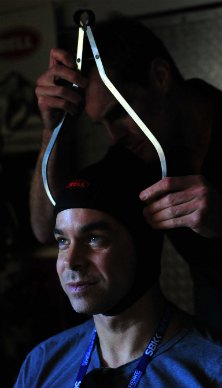

Then, donning what appears to be a Bell swimming cap a Bell technician measures your noggin with an old-school pair of calipers to ensure the data acquisition from its new-school 3-D imaging technology is accurate. This is followed by spinning three revolutions in a chair while a ceiling-mounted device scans your cranium with an invisible laser.

When finished, data is read by a CAD-type software program, measurements are double-checked, necessary adjustments are made then the data is sent to Bell headquarters in Scotts Valley, CA. The entire process takes less than 20 minutes.

“It’s not just a plug and play,” says Pietrzak, “we actually do some fine-tuning based off the information provided.”

At the Bell facility the data is turned into a custom-fit Star Carbon within a couple-day time frame (measurements were taken on Friday and I had my new custom Star by Sunday). Inserting my head into the custom helmet was a familiar but strangely new experience. The ritual of grabbing the chin bar to find the sweet spot isn’t necessary as the custom Star (for lack of a better term) snaps into place, naturally hugging the contours of my cranium.

I did, at first, experience two distinct pressure points, one at the rear and the other at the top front of my skull. After some discussion, double checking measurements and scans we were able to determine that a seam on the removable rear comfort insert to be the culprit. A quick pocket knife-modification was made, and since then the custom Bell Star Carbon has become my go-to helmet.

Two consecutive all-day rides including both street and track while testing the 1290 Super Duke R confirmed the custom Star’s advantage over non-custom-fitted helmets. When I spoke to 2013 AMA Superbike Champion and Bell-sponsored rider, Josh Herrin, at Laguna Seca he boasted how his custom Bell Star didn’t lift or move even with abrupt, race-speed wind-force buffeting, and I experienced the same calmness when circulating the Ascari race track on the naked Super Duke R. For Herrin, a big advantage of the custom Bell Star was not having as tight a fit as he did with a non-custom-fitted helmet to achieve the same results.

And at the end of day two I wasn’t chomping at the bit to remove the helmet as I am wont to do immediately after dismounting a motorcycle. If you’ve ever owned a custom-fit anything – leathers, shoes, golf clubs, etc. – you can certainly relate.

For now, the custom Bell Star program will be available at select events in 2014 (only 25 lucky motorcyclists were given the opportunity at Laguna Seca), so be alert to customizing announcements from Bell. And while Bell’s goal is to eventually bring customization costs down to a price point nearer to the retail price of a non-custom helmet, it’s currently an expensive investment: $650 for the Bell Star Carbon and $450 for the customization process.

For those who can or simply want to afford the custom Bell Star, it’s certainly worth the price of admission, especially considering the retail prices of non-customized helmets from Shoei (X-Twelve $840), Arai (Corsair V $920) and Schuberth (SR1 $969). Or wait a couple years and allow the price to deflate and for Bell to refine the process. Either way, it appears that a promising new helmet technology has finally arrived.

Now, about the helmet visor heads-up display we’ve been asking for…

A former Motorcycle.com staffer who has gone on to greener pastures, Tom Roderick still can't get the motorcycle bug out of his system. And honestly, we still miss having him around. Tom is now a regular freelance writer and tester for Motorcycle.com when his schedule allows, and his experience, riding ability, writing talent, and quick wit are still a joy to have – even if we don't get to experience it as much as we used to.

More by Tom Roderick

Comments

Join the conversation

According to Bell, this was a one shot deal at Laguna Seca. The site for the pre-order at the end of the video no longer exists. :(