44 Views

A Technical Look Inside the Hunwick Hallam Design - Motorcycle.com

by

Ken Edwards

(IC: )

Published: April 1st, 2012

Share

"We set out to design the world's best four-stroke motorcycle powerplant."

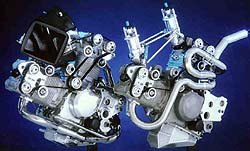

Pioneering Australian engineers Rod Hunwick and Paul Hallam recently unveiled the result of three year's labor during the 1997 World Superbike race meeting at Phillip Island, Australia -- the Hunwick Hallam X1R Superbike. The sleek carbon fiber finish of their bike was like no other, but this motorcycle's real beauty went much deeper then its outer skin: A 1000cc V-twin engine producing better than 170 hp at the rear wheel.

With world beating engineering, world-class design and top-notch build quality, the demand for hand built Hunwick Hallams could make it a bike of desire among motorcyclists worldwide who are willing to pay premium prices for exotic, quality products.

Hunwick Hallam Design Philosophy

The Hunwick Hallam has been designed from first principles. That is, while some motorcycles are designed separately as a powerplant and chassis, for the purposes of its design the H-H has been treated as one singular component. This is evidenced by the fact that as well as its obvious role, the engine crankcases also form a major chassis component of the motorcycle.

In every aspect of the bike, Hunwick Hallam's design philosophy of minimum componentry for maximum effect has been adopted. This and many other aspects already mentioned make the H-H unique.

Heart Of The Business

In every aspect of the bike, Hunwick Hallam's design philosophy of minimum componentry for maximum effect has been adopted. This and many other aspects already mentioned make the H-H unique.

Heart Of The Business

The soul of a Hunwick Hallam is an innovative, air and liquid-cooled, fuel-injected, four-valves-per-cylinder, DOHC, 90-degree V-twin.

Unlike most mass produced engines, the internal geometry of the Hunwick Hallam powerplant has not been compromised by chassis design or geometry. As mentioned above, by design it is the basic component of the motorcycle it powers.

An extremely efficient powerplant, the engine is currently running in both 1000cc (Superbike) and 1100/1350cc (Street) variants. A key element of the design is that this powerplant can be manufactured in a wide range of capacity options.

While many of the specific design elements and dimensions of the 1000cc Superbike powerplant must at this stage remain confidential, what follows is a general description of the Hunwick Hallam 1100/1350cc powerplant.

Crankcases and Bottom End

Unlike most mass produced engines, the internal geometry of the Hunwick Hallam powerplant has not been compromised by chassis design or geometry. As mentioned above, by design it is the basic component of the motorcycle it powers.

An extremely efficient powerplant, the engine is currently running in both 1000cc (Superbike) and 1100/1350cc (Street) variants. A key element of the design is that this powerplant can be manufactured in a wide range of capacity options.

While many of the specific design elements and dimensions of the 1000cc Superbike powerplant must at this stage remain confidential, what follows is a general description of the Hunwick Hallam 1100/1350cc powerplant.

Crankcases and Bottom End

The H-H's cast alloy crankcases are the major structural component of the motorcycle, eliminating the need for a conventional frame. Such unit construction offers no chance to attenuate vibration via rubber engine mounts, therefore the H-H's powerplant has been designed to minimize all sources of conventional V-twin vibration. Particular attention, via the design and layout of the powerplant, has been paid to reduce crankshaft flex, a major contributor to vibration and main bearing fatigue.

The engine also features a revolutionary torsional vibration damping system. This system utilizes a secondary crankshaft oil pump that feeds oil to a mechanical damper.

While the connecting rod big-end bearing is an oversize conventional slipper (or plain) bearing, to minimize frictional losses throughout the powerplant crankshaft mains and all other bearings are either ball or roller units.

Cylinder Heads

The engine also features a revolutionary torsional vibration damping system. This system utilizes a secondary crankshaft oil pump that feeds oil to a mechanical damper.

While the connecting rod big-end bearing is an oversize conventional slipper (or plain) bearing, to minimize frictional losses throughout the powerplant crankshaft mains and all other bearings are either ball or roller units.

Cylinder Heads

Driven directly from the crankshaft, a set of three timing gears fulfill the dual function of providing a combined reference and sync trigger for the ignition, and (via an idler shaft) driving the toothed belt camshaft drive.

Camshafts engage lightweight buckets and shims that actuate fine-stem valves (two intake, two exhaust per cylinder). Set at an ultra-narrow included angle, the paired inlet and exhaust valves are of 38mm and 34mm diameter respectively. The H-H's valve train weight is less than half that of contemporary conventional alternatives.

While the 1100/1350cc engine and Superbike powerplant prototypes currently utilize conventional valve-springs, the H-H valvetrain has actually been designed around a unique variable-pressure pneumatic valve actuation system. Conventional (spring) valve trains account for significant mechanical losses as valve closing pressures must be higher than necessary at low rpm to be able to cope with high rpm operation. Given the constant-pressure pneumatic valve actuating systems currently in use in Fl car racing demonstrate significant power gains at high rpm, the potential power gains at all rpm from a variable-pressure pneumatic system is manifest.

The Hunwick-Hallam variable pneumatic system also addresses two other significant negatives associated with F1-style pneumatic valve set-ups: The need to carry a reservoir of compressed gas (usually nitrogen) and the discharge of that gas into the atmosphere.

The H-H's combustion chamber features a centrally-located spark-plug, full radial squish design and Axial Targeted Combustion (ATC). These features and optimum combustion chamber shape (in concert with the special piston crown design) produce efficient combustion characteristics at a wide range of compression ratios.

Thanks to the head's 45-degree induction angle, the powerplant realizes a significant downdraft effect for superior cylinder filling. On the exhaust side a reverberation barrier is cast into the head for optimal exhaust harmonics and flow The Hunwick Hallam cylinder head layout is also innovative in its three-piece design. The cylinder head proper incorporates a water jacket, valve guides and seats and intake and exhaust ports, while the camshafts, valve buckets and shims, etc. are housed in upper and lower cam boxes. As well as facilitating easy servicing, the latter units can easily be replaced if damaged.

Engine Management

Camshafts engage lightweight buckets and shims that actuate fine-stem valves (two intake, two exhaust per cylinder). Set at an ultra-narrow included angle, the paired inlet and exhaust valves are of 38mm and 34mm diameter respectively. The H-H's valve train weight is less than half that of contemporary conventional alternatives.

While the 1100/1350cc engine and Superbike powerplant prototypes currently utilize conventional valve-springs, the H-H valvetrain has actually been designed around a unique variable-pressure pneumatic valve actuation system. Conventional (spring) valve trains account for significant mechanical losses as valve closing pressures must be higher than necessary at low rpm to be able to cope with high rpm operation. Given the constant-pressure pneumatic valve actuating systems currently in use in Fl car racing demonstrate significant power gains at high rpm, the potential power gains at all rpm from a variable-pressure pneumatic system is manifest.

The Hunwick-Hallam variable pneumatic system also addresses two other significant negatives associated with F1-style pneumatic valve set-ups: The need to carry a reservoir of compressed gas (usually nitrogen) and the discharge of that gas into the atmosphere.

The H-H's combustion chamber features a centrally-located spark-plug, full radial squish design and Axial Targeted Combustion (ATC). These features and optimum combustion chamber shape (in concert with the special piston crown design) produce efficient combustion characteristics at a wide range of compression ratios.

Thanks to the head's 45-degree induction angle, the powerplant realizes a significant downdraft effect for superior cylinder filling. On the exhaust side a reverberation barrier is cast into the head for optimal exhaust harmonics and flow The Hunwick Hallam cylinder head layout is also innovative in its three-piece design. The cylinder head proper incorporates a water jacket, valve guides and seats and intake and exhaust ports, while the camshafts, valve buckets and shims, etc. are housed in upper and lower cam boxes. As well as facilitating easy servicing, the latter units can easily be replaced if damaged.

Engine Management

The Hunwick Hallam powerplants feature multi-sensor computerized engine management systems that control both EFI and ignition functions. The V-twin is designed to comply with all existing and future emissions legislation both in Australia and key export markets including Japan, the USA and most European countries.

In the case of the 1100/1350cc powerplant, its system allows three-dimensional fuel and spark mapping via a single-injector per cylinder full sequential set-up. The X1R Superbike powerplant uses a twin-injector system, phasing overhead injectors relative to engine load and rpm variables.

A more advanced fuel mapping system currently earmarked for the X1R Superbike features a multi-channel data logging facility with provision for a number of other performance functions currently under examination. Ignition is via sparkplug-top coils with a combined reference and sync trigger provided via the crank driven timing gears. This configuration allows cambelt reinstallation or breakage without the desynchronization of any bottom-end engine components relative to engine management.

Cooling and Lubrication Systems

The H-H powerplants are both air and water-cooled. External finning on the cylinder head and cylinder enhance the dissipation of heat to the atmosphere from the water jacket. This dissipation is also aided by the rigid connection of the engine to the vestigial steering head casting that also acts as a heat sink. In addition, the engine uses a fully-controlled pressurized liquid system with ducted radiator and thermostatically controlled fan.

The V-twin's engine lubrication system is another unique feature

The V-twin's engine lubrication system is another unique feature. Effectively a wet sump design functioning with the main pump as a low pressure scavenger, the set-up utilizes the crankshaft as its own oil pump. This design reduces the size requirements of the primary oil pump that once again is a direct saving of engine power. Nonetheless, even at low rpm the design produces oil pressure and volume far beyond that required by current engine set-up. This should provide for future developments, including a clutchless electraulic semi-automatic transmission.

Transmission and Gearbox

The Hunwick Hallam powerplants feature vertically-stacked two-shaft constant-mesh gearboxes (five-speed in the case of the 1100/1350cc and six-speed for the Superbike). A conventional hydraulically-actuated wet multiplate clutch is driven directly from the crankshaft and spins an input shaft located below the gearbox output (counter) shaft. Final drive is via low-maintenance O-ring chain.

Unconventional in its configuration, the Hunwick Hallam's gearbox is designed as a modular unit. This set-up minimizes engine length, maximizes access for routine maintenance and is another example of the integrated nature of Hunwick Hallam's design.

Development of an electraulic transmission is currently under way. This system can be used as a clutchless semi-automatic system for racetrack applications or as a fully-automatic system suitable for the Power Cruiser, incorporating traction control. Driven by excess engine oil pressure, the electraulic system requires only a small electronic clutch lever and up/down gearshift button.

Serviceability

In the case of the 1100/1350cc powerplant, its system allows three-dimensional fuel and spark mapping via a single-injector per cylinder full sequential set-up. The X1R Superbike powerplant uses a twin-injector system, phasing overhead injectors relative to engine load and rpm variables.

A more advanced fuel mapping system currently earmarked for the X1R Superbike features a multi-channel data logging facility with provision for a number of other performance functions currently under examination. Ignition is via sparkplug-top coils with a combined reference and sync trigger provided via the crank driven timing gears. This configuration allows cambelt reinstallation or breakage without the desynchronization of any bottom-end engine components relative to engine management.

Cooling and Lubrication Systems

The H-H powerplants are both air and water-cooled. External finning on the cylinder head and cylinder enhance the dissipation of heat to the atmosphere from the water jacket. This dissipation is also aided by the rigid connection of the engine to the vestigial steering head casting that also acts as a heat sink. In addition, the engine uses a fully-controlled pressurized liquid system with ducted radiator and thermostatically controlled fan.

The V-twin's engine lubrication system is another unique feature

The V-twin's engine lubrication system is another unique feature. Effectively a wet sump design functioning with the main pump as a low pressure scavenger, the set-up utilizes the crankshaft as its own oil pump. This design reduces the size requirements of the primary oil pump that once again is a direct saving of engine power. Nonetheless, even at low rpm the design produces oil pressure and volume far beyond that required by current engine set-up. This should provide for future developments, including a clutchless electraulic semi-automatic transmission.

Transmission and Gearbox

The Hunwick Hallam powerplants feature vertically-stacked two-shaft constant-mesh gearboxes (five-speed in the case of the 1100/1350cc and six-speed for the Superbike). A conventional hydraulically-actuated wet multiplate clutch is driven directly from the crankshaft and spins an input shaft located below the gearbox output (counter) shaft. Final drive is via low-maintenance O-ring chain.

Unconventional in its configuration, the Hunwick Hallam's gearbox is designed as a modular unit. This set-up minimizes engine length, maximizes access for routine maintenance and is another example of the integrated nature of Hunwick Hallam's design.

Development of an electraulic transmission is currently under way. This system can be used as a clutchless semi-automatic system for racetrack applications or as a fully-automatic system suitable for the Power Cruiser, incorporating traction control. Driven by excess engine oil pressure, the electraulic system requires only a small electronic clutch lever and up/down gearshift button.

Serviceability

Hunwick Hallam's holistic design brief includes an emphasis on ease of maintenance and repair. Nothing is more complex than it has to be - an approach diametrically opposed to most high-performance engineers.

Ease of maintenance was considered vital, and to a certain extent so is the ability of a design to cope with clumsy maintenance - be it at the hands of an owner or professional. As mentioned previously, engine management and ignition functions require no servicing or adjustment, nor do the pneumatic valve actuation or fuel-injection systems. In addition, the bike's EMS brain has a comprehensive diagnostic function that can be read with appropriate service equipment.

Aside from attention to design to utilize readily available bearings and seals, for instance, the 1350cc Power Cruiser engine has one other very unique property. If the bike is disassembled or a cambelt breaks, by virtue of its combustion chamber and piston design it is impossible for the valves to touch the pistons. This means an owner could literally coast to a stop, fit a new cambelt, incorrectly time it and attempt to ride the bike, all without doing any damage. The Hunwick Hallam design is, in a word -- Bulletproof.

Ease of maintenance was considered vital, and to a certain extent so is the ability of a design to cope with clumsy maintenance - be it at the hands of an owner or professional. As mentioned previously, engine management and ignition functions require no servicing or adjustment, nor do the pneumatic valve actuation or fuel-injection systems. In addition, the bike's EMS brain has a comprehensive diagnostic function that can be read with appropriate service equipment.

Aside from attention to design to utilize readily available bearings and seals, for instance, the 1350cc Power Cruiser engine has one other very unique property. If the bike is disassembled or a cambelt breaks, by virtue of its combustion chamber and piston design it is impossible for the valves to touch the pistons. This means an owner could literally coast to a stop, fit a new cambelt, incorrectly time it and attempt to ride the bike, all without doing any damage. The Hunwick Hallam design is, in a word -- Bulletproof.

Ken Edwards

More by Ken Edwards

Published April 1st, 2012 6:00 AM

Motorcycle Insurance

Comments

Join the conversation