29 Views

by

Alex Edge

(IC: )

Published: August 10th, 2007

Share

At Area P, it’s a family affair for the Bryants. Kerry, seated at center with Australian Cattle Dog Zorro, is the progenitor. Sons Kenny (aboard the ZX-14) and Kelly (on the left) get their hands dirty with fabrication and production. At right is Kerry’s wife, Jenny, who handles sales and marketing.

A display rack in the waiting room shows off some of Area P’s products - a few complete mufflers, as well as some of the components used to build them (perforated cores, billet end caps, exhaust hanger brackets) and offers a small selection of Area P apparel. The headers lying on the floor are prototypes Area P built while working towards a final design for a customer.

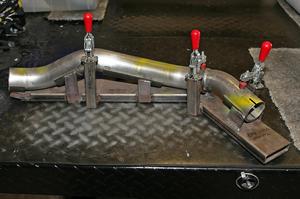

Here’s a close look at the Area P’s header pipes on a Kawasaki ZX-14 in a very early stage of development. In the quest for ultimate performance, the Bryants go through multiple prototypes, each one featuring slight changes to areas like the collector or the length and diameter of the header primaries.

Alex Edge

More by Alex Edge

Published August 10th, 2007 6:00 AM

Motorcycle Insurance

Comments

Join the conversation